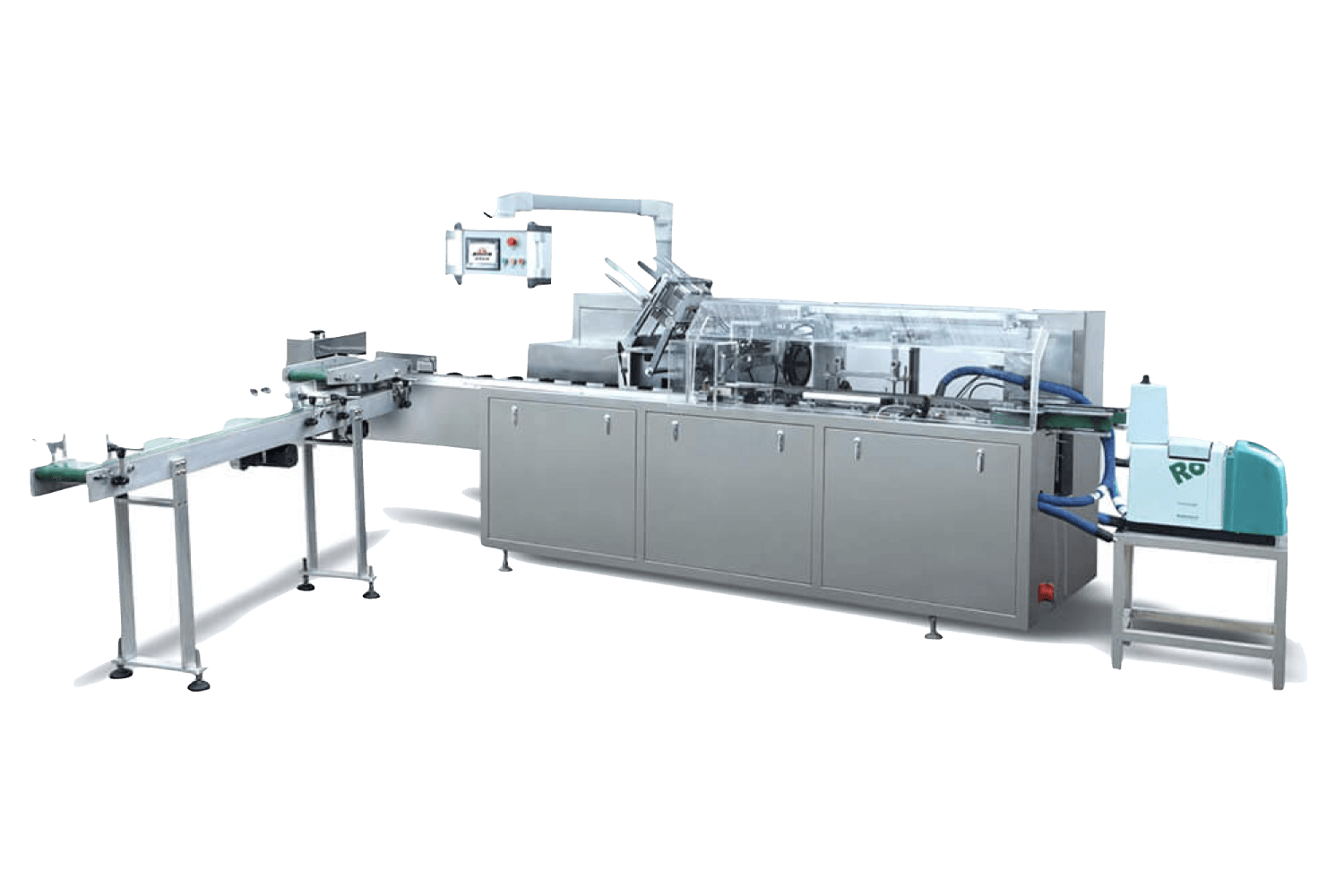

CSZ-130B Food Bulk Cartoning Machine

Packages with multi-materials can be well applied on our cartoning machine,can be customized as your request.

Technical Parameter

| Model | CSZ-130B |

| Packing speed | 30-80cartons/min |

| Size of package | L(90-260)mm×W(60-130)mm×H(30-90)mm |

| Cardboard material | 250-450g/㎡ |

| Instruction material | 60-70g/㎡ |

| Instruction size (Unfold) | (80-150) x (90-170)mm |

| Instruction size (Fold) | (1-4) Fold |

| Motor power | 1.5kw |

| Power supply | 380V 50HZ or 220V 50HZ |

| Minimum Air pressure | 0.5-0.8 Mpa |

| Air consumption | 120-160L/min |

| Maximum noise | 80dB |

| Overall dimension | L3800mm×W1350mm×H1900mm |

| Weight | 1500Kg |

Electric Configuration

| PLC | CPIE-N30DT-D/Omron |

| PLC Extened Module | CPIE-C1F11/Omron |

| Touch Screen | NB7W-TW00B/Omron |

| Sensor | E3Z-D61/Sick |

| Frequency | 3G3JZ-A4015/Omron |

| Relay | MY2 NJ24V/Omron |

| Button | XB2/Schneider |

| Emergency Stop | ZB2 BC4D/Schneider |

| Electromagnetic Valve | 4V210-08/Airtac |

| Pressure Regulator Valve | BFR-2000/Airtac |

| Proximity Switch | TL-Q5MC1/Omron |

| AC contactor | LC1E3210M5N/Schneider |

| Air switch | 3P32A 1P6A/Schneider |

| Vaccum Sounder | ABM20-C/SMC |

Machine Introduction&Features

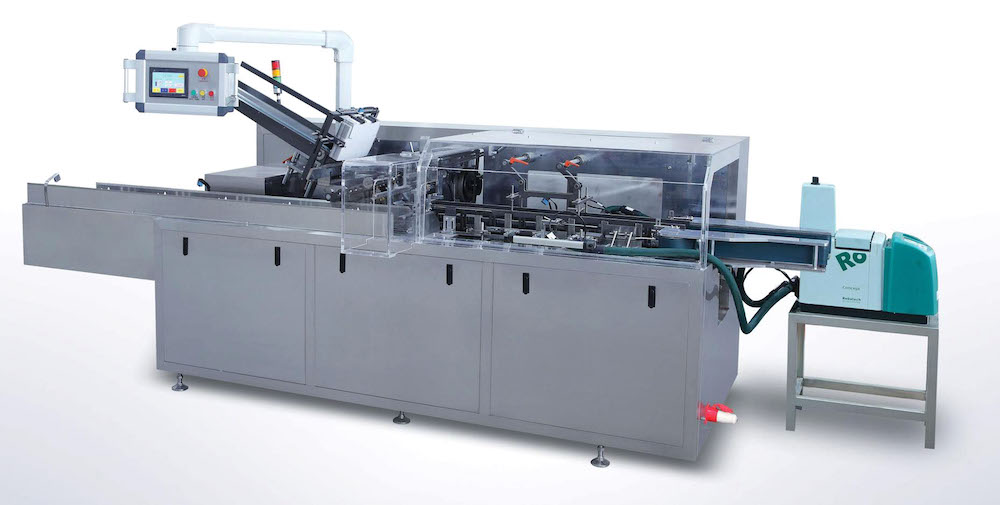

The CSZ-130B box packaging machine is a versatile solution for packaging a wide range of products, including pharmaceuticals, stationery, and small consumer goods. It features adjustable molds that can be quickly and easily changed to suit different products, with dimensions ranging from 90-260mm in length, 60-130mm in width, and 30-90mm in height.It operates fully automated, retrieving packages from the storage area, opening the cartons, packing the products, and sealing the cartons with no manual intervention required. It can be used as a standalone machine or integrated into a production line with other cartoning machines, such as blister pack cartoners and hot melt glue cartoners.

This cartoning machine boasts an automated delivery system that efficiently folds instruction booklets, opens cartons, packs objects and instructions, seals packages, and eliminates waste.

With its stable structure and low noise level of less than 85dB, this packaging machine offers a reliable and quiet packaging solution.

Controlled by a PLC with a touch screen interface, making it user-friendly and easy to operate.

An electro-optical tracking system helps to save materials, while an empty package detection system ensures that only properly filled packages are sent out.

Adjusting the machine for different product sizes is easy and quick, without the need for mold changes.

The protection system automatically shuts down the machine when items are not correctly positioned, and the main drive motor has an overload protection device for added safety and reliability.

Can be euipped with a aluminum plastic packaging machine, flow-pack wrapping machine, 3D packaging machine, bottling line, filling machine, labeling machine, inkjet printer, online weighing instrument etc.

Product Details

| Name | Description | |

|---|---|---|

|

Feeding System | It is the loading unit, allowing materials to be packaged. |

|

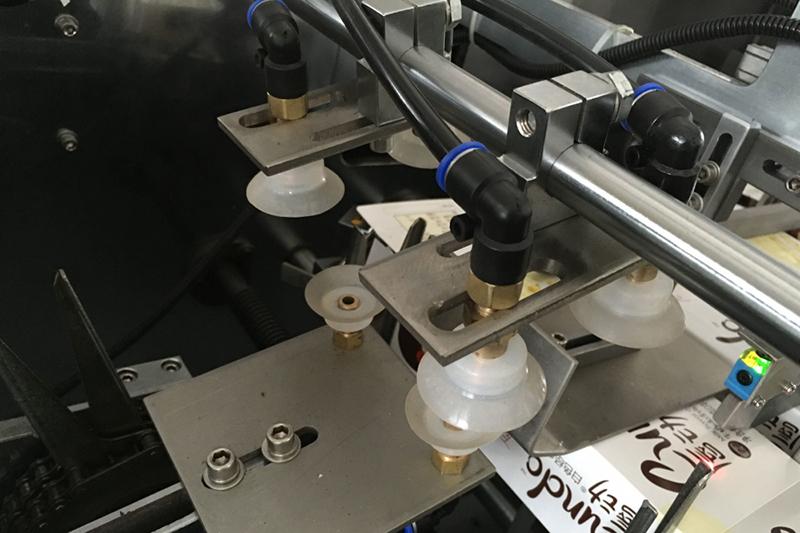

Box Forming Device | The double suction cup opens the carton precisely and quickly. It will send the carton to the bottom of the suction cup, then place it in chains. |

|

Box Storage | The carton store has a board that can move to adjust the package length. Both the front and back frame are connected by a slot hole in order to fit different packaging widths. |

|

Sensor | German brand SICK infrared protector is able to detect and track the whole system automatically making sure this packaging machine runs normally. |

|

Pushing Device | The double pusher head ensures items are pushed into the carton. If items get stuck, the machine will shut down and sound an alarm. |

|

Touch Screen | A Japanese Omron touch screen is used, ensuring stable and easy operation. It displays faults, alarms, and finished product count, making it easy to matain and fix any problems that arise. |

FAQs

Mostly used in food, pharmaceuticals, and consumer industry.

Yes, definitely can be customized as your products.

It depends on your products size and the model of the machine.

Yes, cartooning machines are designed to be user-friendly and easy to operate.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!