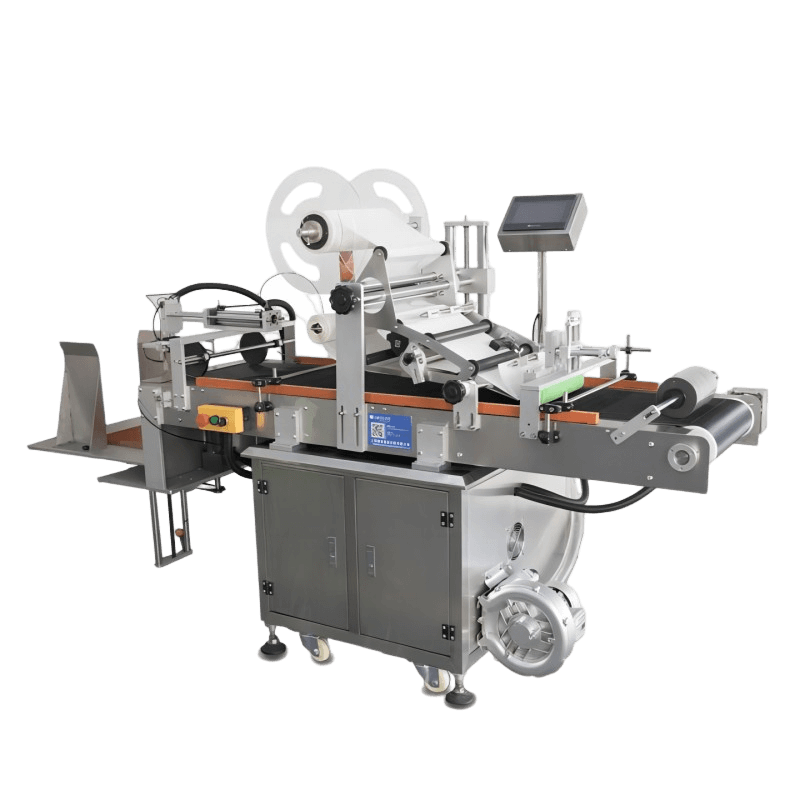

Automatic vacuum pouch labelling machine

Designed to label soft materials, such as bags, and features a suction cup device that automatically picks up the bags and places them onto the conveyor to be labeled.

Technical Parameter

| Model | BGJ-F300 |

| Labeling speed | 60-100pcs/min |

| Labeling material | Self-adhesive sticker, opaque or transparent label |

| Applicable bag size | L:80-350mm,W:80-300mm,Height:0-2mm |

| Applicable label size | L:10-80mm,W:10-80mm |

| Labeling precision | +/-1mm(exclude the product and label deviation) |

| Power supply | 220V 50HZ |

| Overall dimension | L750mm×W580mm×H1450mm |

| Weight | 250Kg |

Electric Configuration

| PLC | FX3sA-30MT/Mitsubidhi |

| Touch Screen | TK6070iP/Weinview |

| Sensor | D10BFP/Banner |

| Labeling Motor | 2S86Q-030B8/KINCO |

| Labeling Motor Drive | 2M860/KINCO |

| Converyor Motor | D63B14-0.18KW+FB/Li-ming |

| Frequency converter | S800-2S0.4G/SAVCH |

| Emergency Stop | XB2-BS542/Omron |

| Relay | LY2N-J 24VDC/Omron |

Machine Introduction&Features

The automatic paging labeling machine is composed of mechanisms for paging, labeling, paper collection, sensing, and transmission. This equipment is independently researched and designed by the company, and it can automatically sense and apply labels, ensuring precise and aesthetically pleasing labeling results, as well as accurate recognition of product weights with a lower error rate. The device can be customized to meet specific customer requirements.

Food and chemical industry, garments,printing and packaging industries.

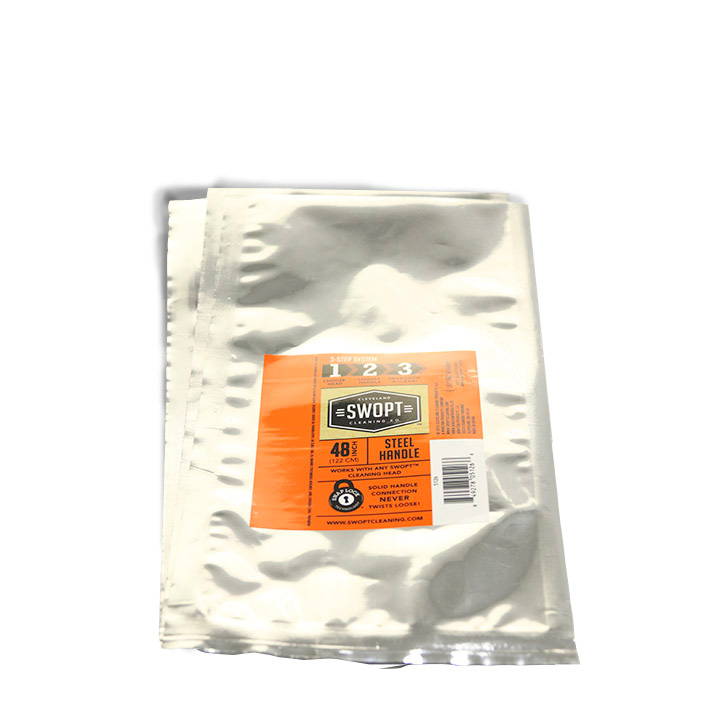

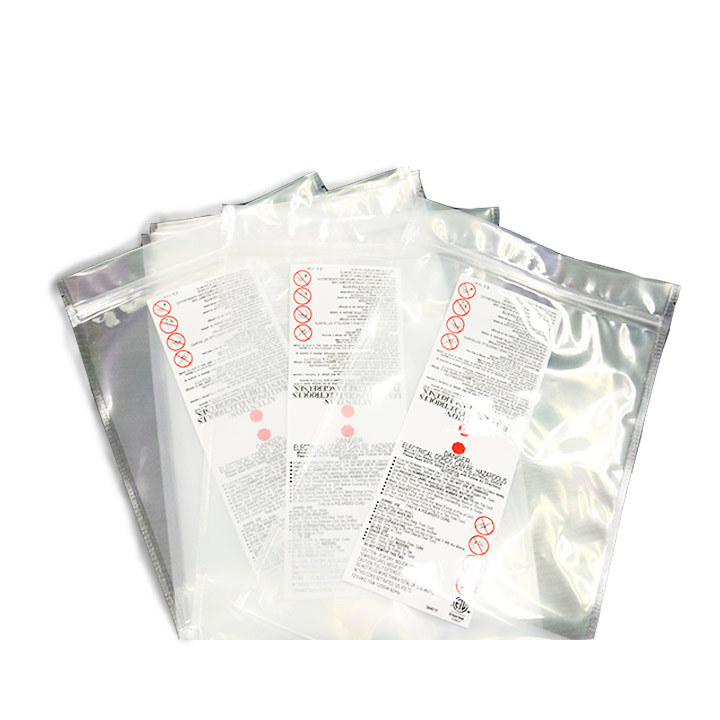

Soft plsatic bags.

Automatically feeding bags,detect labels, improve the labeling efficiency of products, accurate labeling position, good quality, and high stability. Avoid problems casued by manual labeling,such as skewed labeling, bubbles and wrinkles, irregular labeling positions, etc.

The main materials of the equipment are stainless steel and high-grade aluminum alloy, with a solid and elegant overall structure,simple operation and maintenance.

The equipment is customized according to customer samples, with a labeling accuracy of +1mm, which can be adjusted within the technical specifications.

The structure is small and occupies a small area, which is convenient for equipment movement and placement. The equipment includes positioning devices, fault alarm production counting and an optional printing functions, etc.

Product Gallery

Product Details

| Name | Description | |

|---|---|---|

|

Material Storge | It is the loading unit, allowing materials to be palced for feeding. |

|

Suction Feeding Device | Automatically feeding the materials onto the converyor by suction device. |

|

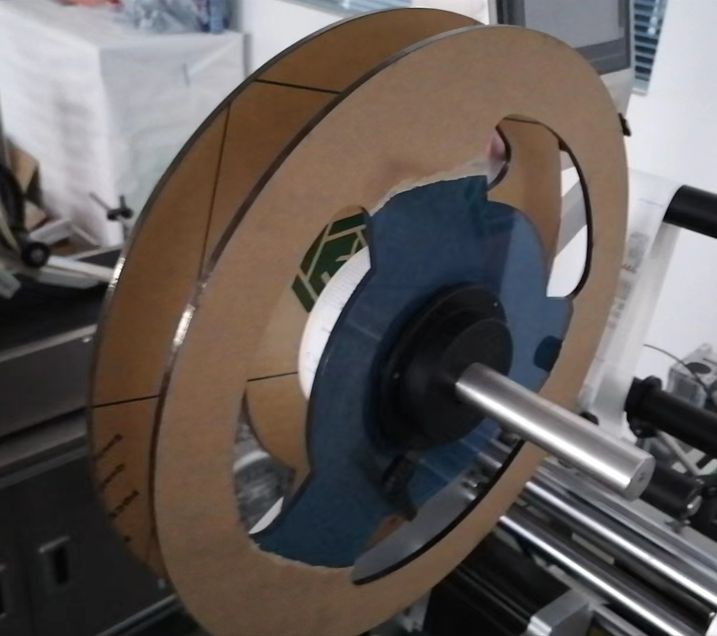

Label Roll Holder | The Label Roll Holder features a spindle or mandrel that is adjustable to accommodate different label roll sizes and widths. It is also designed to minimize tension and prevent the labels from wrinkling or jamming during the dispensing process. |

|

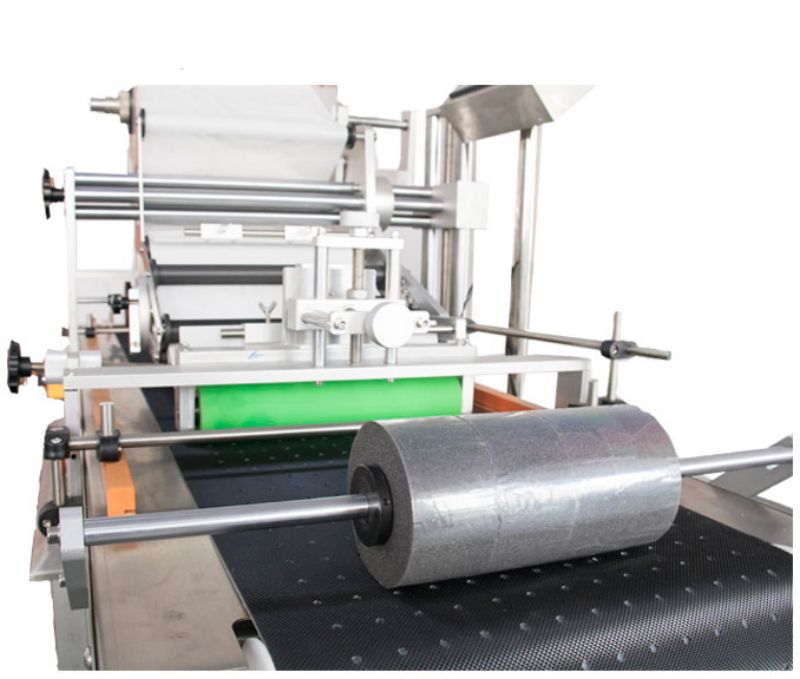

Labeling Head | This is the part of the machine that applies the label to the product. The labeling head typically includes a labeling mechanism that dispenses the label onto the product and a conveyor that moves the product through the machine. |

|

Touch Screen | The touch screen is equipped with intuitive and responsive controls that allow operators to adjust various parameters such as labeling speed, label placement, and label size. It may also feature advanced functions such as automatic label detection, label counting, and error logging. |

|

Conveyor System | It is an important component, which transports the products to be labeled from one position to the labeling position, ensuring smooth transportation of the products and accurate labeling.can be adjusted and customized according to the size and shape of different products. |

|

Electrical Control Cabinet | The Electrical Control Cabinet of the adhesive labeling machine is an essential component that houses the electronic control system responsible for regulating and monitoring the machine's operation. It typically consists of a metal enclosure that is designed to protect the sensitive electronic components from damage and environmental factors. |

FAQs

Our labeling machines are versatile and can label a variety of products, including round objects,suqare objects and objects with flat surface etc.

There are sleeve labeling machine,hot melt glue labeling machine,self-adhesive labeling machine and cold glue labeling machine,can meet your different labeling request.

Yes, our labeling machines are compatible with various container materials, including plastic, glass, and metal.

Yes, it can handle various label sizes and shapes, including wrap-around, front and back, and top and bottom labels.

Our labeling machines use advanced sensors and precision mechanics to ensure accurate label position, even on irregularly shaped containers.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!