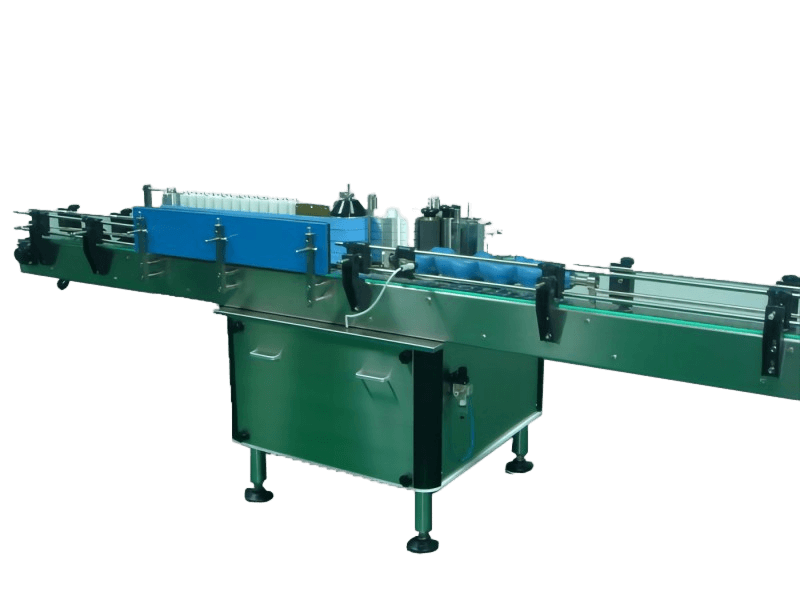

Cold Glue Labeling Machine

The cold glue labeler is designed for round bottle labeling, suitable for all kinds of round bottle labeling. Widely used for round containers in food factories, can factories, liquor factories, general chemical plants, and pharmaceutical enterprises.

Technical Parameter

| Model | CG-S100 |

| Labeling speed | 30-100 bottle/min |

| Labeling material | Paper |

| Labeling precision | ±1mm |

| Conveyor length | 3m |

| Applicable bottle diameter | 30-110mm |

| Applicable label length | 30-300mm |

| Applicable label width | 30-150mm |

| Power supply | 1.2KW |

| Voltage | 380V 50HZ |

| Weight | 550KG |

Electric Configuration

| PLC | LG/Korea |

| Main drive motor | MOTOVARIO/Italy |

| Conveyor motor | LM/Taiwan |

| Main transducer | Delta/Taiwan |

| Vacuum machine | EMORE HORN/Taiwan |

| Photoelectric control | Omron/Japan |

| Bearing | NSK/Japan |

| Control button | Schneider/France |

| Vacuum belt | NITTA/Japan |

| Circuit breaker | Schneider/France |

| Solenoid valve | SMC |

Machine Introduction&Features

The cold glue labeling is an ideal labeler for front, shoulder, neck ring labels and tamper-evident seals in humid environments and on wet container surfaces. Cold glue is also an excellent method for heat-sensitive materials and reduces the risk of burn-related worker injuries. Glue is dispensed directly onto the container and solidified during the label application. This labelling machine is a fully-automatic line-type machine for cold glue labelling, which is suitable for different container sizes and round bottle shapes with high labelling accuracy with low glue consumption.

Glue tank and stainless steel roller have precise processing to ensure leak-free operation

Special rubber roller is processed through multiple steps to ensure it is wear-resistant, non-deformable, and applies glue evenly and lightly, thereby saving glue.

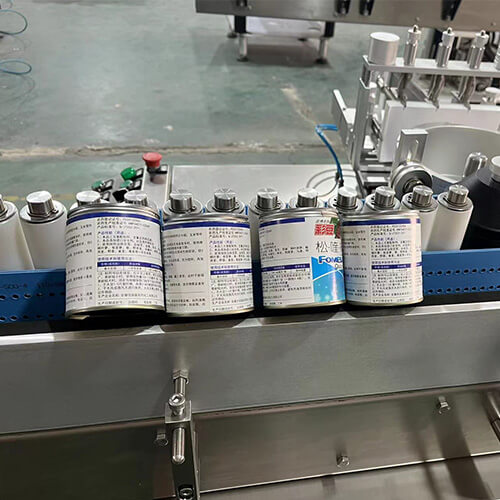

Vacuum suction label with a belt ensures smooth pasting of labels onto bottles.

Photoelectric sensor detects bottles to ensure there are no unlabeled bottles.

The use of a frequency converter allows for free adjustment of the motor speed, thereby controlling labeling capacity.

It can operate as a standalone machine or be connected to a production line.

Equipped with a manual adjustment device, making it easy to adjust and operate.

Product Gallery

Product Details

| Name | Description | |

|---|---|---|

|

Bottle Feeding Screw | It is a rotating mechanism that transports empty or filled bottles or other containers from one end to the next section. |

|

Label Storge Box | It is a box or compartment for storing labels, which stores a large number of labels and provides them for subsequent processing. |

|

Gluing Device | The glue tank and stainless steel roller are precisely machined for perfect compatibility, and the glue can be used and extracted at any time without leakage. |

|

Vacuum Label Pickup | It is a vacuum suction cup or mechanism that picks up the label from the storage box and transfers it for labeling. |

|

Labeling Device | It is a mechanical pressure system that attaches the label to the bottle or container, completing the labeling process. |

FAQs

Our labeling machines are versatile and can label a variety of products, including round objects,suqare objects and objects with flat surface etc.

There are sleeve labeling machine,hot melt glue labeling machine,self-adhesive labeling machine and cold glue labeling machine,can meet your different labeling request.

Yes, our labeling machines are compatible with various container materials, including plastic, glass, and metal.

Yes, it can handle various label sizes and shapes, including wrap-around, front and back, and top and bottom labels.

Our labeling machines use advanced sensors and precision mechanics to ensure accurate label position, even on irregularly shaped containers.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!