High Speed PET Blow Molding Machine

Our high speed blow molding machine is an eco-friendly, full electric PET blow molding machine. Its advanced technology ensures high output and low power consumption, making it a cost-effective and efficient solution for manufacturing needs. It meets the demands of various industries, including food and beverage, cosmetics, and pharmaceuticals. Investing in this machine enhances production efficiency while reducing environmental impact.

Technical Parameter

| Model | TURBO-4L | TURBO-6S | TURBO-6L | TURBO-9S |

| Cavity Pitch | 114.3mm | 76.2mm | 114.3mm | 76.2mm |

| Cavity Quantity | 4 | 6 | 6 | 9 |

| Max Bottle Volume | 2L | 750ml | 2L | 750ml |

| Neck Size | 18-38mm | 18-38mm | 18-38mm | 18-38mm |

| Max Bottle Diameter | 105mm | 70mm | 105mm | 70mm |

| Max Bottle Height | 330mm | 260mm | 330mm | 260mm |

| Capacity | 4500-5500BPH | 9000-10000BPH | 6500-8000BPH | 12000-13000BPH |

| Max Heating Power | 50KW | 65KW | 85KW | 85KW |

| Install Power | 60KW | 70KW | 90KW | 90KW |

| Blowing Pressure | 2.5-4.0Mpa | 2.5-4.0Mpa | 2.5-4.0Mpa | 2.5-4.0Mpa |

| Main Machine Dimension | 3.5*2.0*2.3m | 4.3*2.15*2.25m | 5.8*2.2*2.3m | 5.8*2.2*2.3m |

| Preform Unscrambler Dimension | 1.1*0.9*2.4m | 1.3*0.6*2.75m | 1.4*0.8*3.03m | 1.4*0.8*3.03m |

| Auto Loader Dimension | 0.97*2.5*3.2m | 1.16*1.6*3.3m | 1.16*1.6*3.3m | 1.16*1.6*3.3m |

| Machine Weight | 5000KGS | 5500KGS | 8000KGS | 8000KGS |

Electric Configuration

| PLC | Mitsubishi |

| Touch Screen | Mitsubishi |

| Proximity Sensor | Autonics |

| Gear Motor | ECERGEAR |

| Sealing Cylinder | Airtac |

| Clamping Cylinder | SMC |

| Rotary Cylinder | SMC |

| Transfer Motor | Xinjie |

| Preform Feeding Motor | Xinjie |

| High Pressure Valves | Parker |

| Low Pressure Valves | Festo |

| Magnetic Sensor | Airtac |

| Contactor | Schneider |

Machine Introduction&Features

The Liner full-auto high speed stretch blow molding machine is a state-of-the-art PET blow molding machine developed by our company. This cutting-edge technology is fully electric and high-speed, enabling it to produce various types of bottles below 2 litres, including food packaging bottles, edible oil bottles, soda and mineral water bottles, fruit juice bottles, wine bottles, and cosmetics bottles.

Utilizing a motion control system centered on a servo system, the fully-automatic high-speed servo blow molding machine ensures precise control of all machine actions and perfect coordination, resulting in a 2x increase in action speed while reducing collisions and wear between parts, thereby extending the machine’s lifespan.

The machine is computer-controlled with a clear and easy-to-use operation interface.

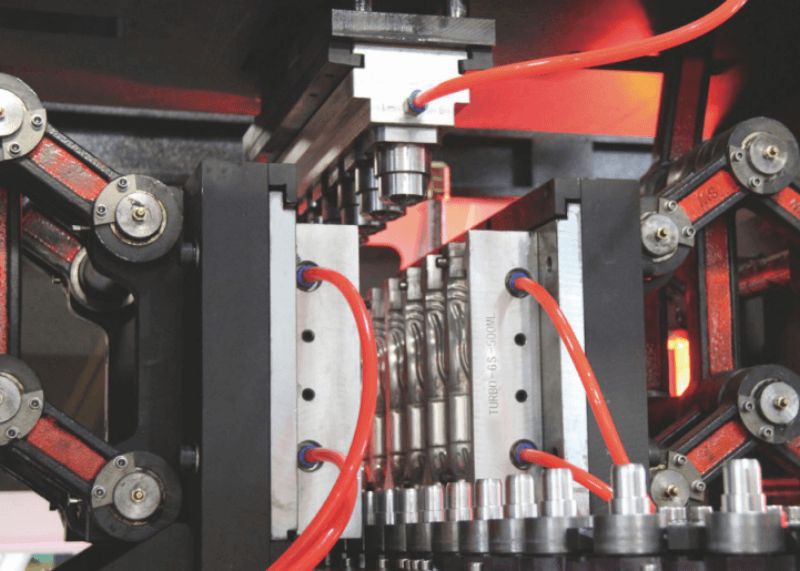

The machine adopts a drawer-type mold positioning design, making mold replacement quick and easy. Aluminum molds can be easily replaced within half an hour.

The machine is equipped with a fully-enclosed safety door system, ensuring the safety of the operating personnel to the greatest extent.

The machine is equipped with a multi-point photoelectric detection system to protect the positioning system, clamping system, and stretching system during operation.

Our Equipment Usage

Product Details

| Name | Description | |

|---|---|---|

|

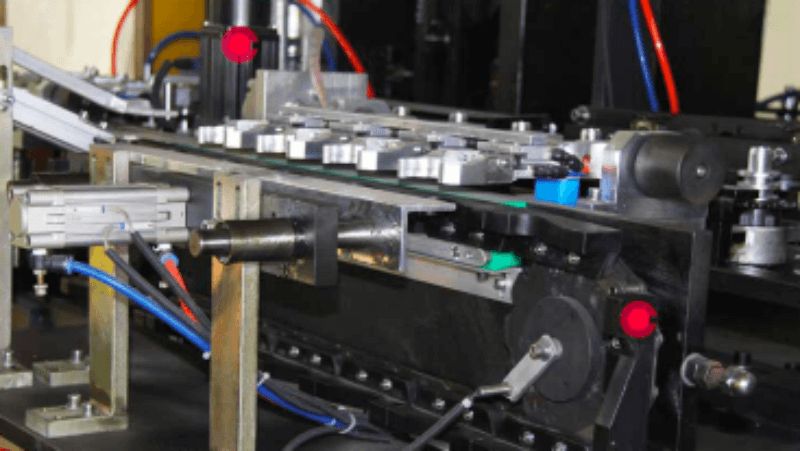

Perform Feeding System | Servo motors are used to separate the preform, effectively solving the problem of wear between the stuck and blown preforms. |

|

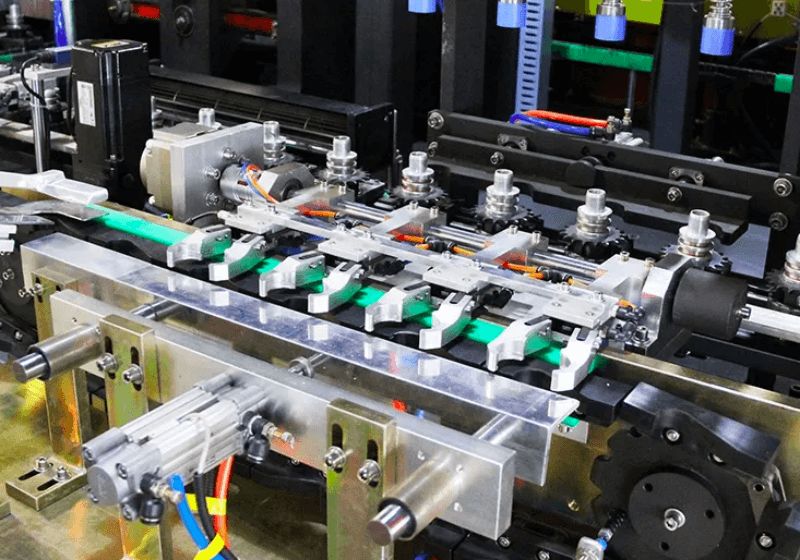

Preform Transfer System | The horizontal movement of the blown bottle system is driven by a servo motor, which can achieve twice the speed of the cylinder push mode, making it more precise and faster. |

|

Mold Clamping System | The reaction time can be shortened to 50% of the traditional pneumatic drive, with a simple structure, no wear, and an extended service life. |

|

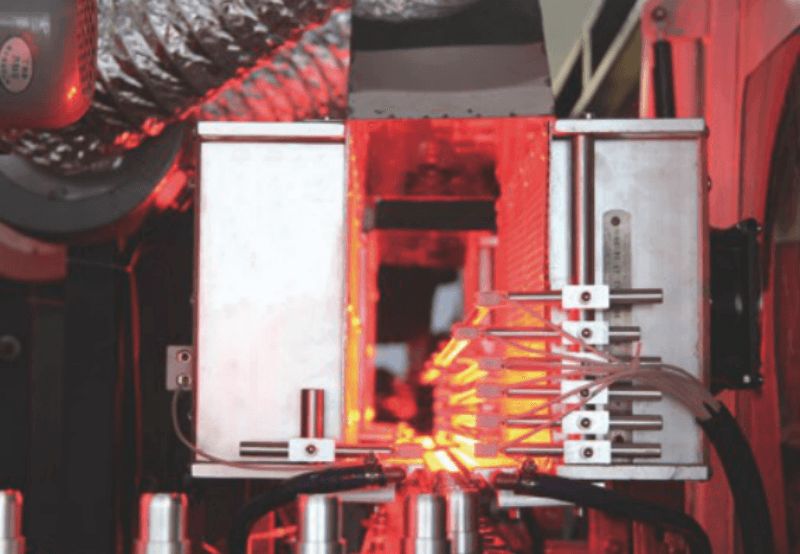

Constant Temperature Oven | Our efficient constant temperature oven uses advanced infrared lamps, individually controlled layers, intelligent temperature control, self-rotation for even heating, and neck cooling with recycling water to prevent deformation. |

FAQs

The process starts by melting plastic resin and then injecting it into a mold. Once the plastic has cooled and solidified, a hollow tube called a parison is formed. The parison is then clamped into a mold and air is blown into it, causing it to expand and take on the shape of the mold.

There are several types of blow molding machines, including extrusion blow molding machines, injection blow molding machines, and stretch blow molding machines.

Yes, our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!