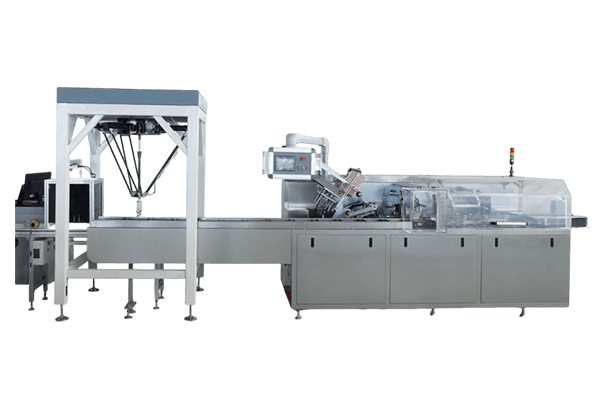

CSZ-250B Robot Arm Cartoning Machine

Catoning machine can be equipped with robot arm to automatically feeding the materials to the converyor before pushing into the boxes.

Technical Parameter

| Model | CSZ-250B |

| Packing speed | 30-40cartons/min |

| Size of package | L(100-350)mm×W(150-250)mm×H(20-90)mm |

| Cardboard material | 250-450g/㎡ |

| Instruction material | 60-70g/㎡ |

| Instruction size (Unfold) | (80-150)x(90-170)mm |

| Instruction size (Fold) | (1-4)Fold |

| Motor power | 1.5kw |

| Power supply | 380V50HZ |

| Minimum Air pressure | “0.5-0.8Mpa” |

| Air consumption | 120-160L/min |

| Maximum noise | 80dB |

| Overall dimension | L5000mm×W1350mm×H1900mm |

| Weight | 1450Kg |

Electric Configuration

| PLC | CPIE-N30DT-D/Omron |

| PLC Extened Module | CPIE-C1F11/Omron |

| Touch Screen | NB7W-TW00B/Omron |

| Sensor | E3Z-D61/Sick |

| Frequency | 3G3JZ-A4015/Omron |

| Relay | MY2 NJ24V/Omron |

| Button | XB2/Schneider |

| Emergency Stop | ZB2 BC4D/Schneider |

| Electromagnetic Valve | 4V210-08/Airtac |

| Pressure Regulator Valve | BFR-2000/Airtac |

| Proximity Switch | TL-Q5MC1/Omron |

| AC contactor | LC1E3210M5N/Schneider |

| Air switch | 3P32A 1P6A/Schneider |

| Vaccum Sounder | ABM20-C/SMC |

Machine Introduction&Features

The CSZ-250B cartoning machine equipped with a Robot Arm system,it is designed for automatic pick up the materials onto the conveyor for pushing into the carton. With customizable options for L(100-350)mm×W(100-250)mm×H(20-100)mm, it is perfect for various products including medicines, auto parts, food, cosmetics and other consumer goods. This versatile machine is equipped to automatically open, pack, and seal cartons with ease. It can function independently or as part of a production line, alongside blister pack cartoning machines, hot melt dispensing machines, and other devices.

This cartoner conforms to the health standards of various industries.

The electrical components are sourced from reliable suppliers in countries such as Japan, France, and Korea, ensuring stability and durability.

It can automatically feed materials, open cartons, pack items, seal packages, and eliminate waste. The structure is reasonable and easy to operate.

Equipped with a PLC system and man-machine interface, the machine can adjust its speed using stepless frequency conversion. It runs in a highly automatic mode and is easy to operate and adjust.

The machine has an automatic overload shutdown feature, ensuring the safety of both the staff and the machine.

Empty packages or cartons without instruction booklets can be eliminated to prevent empty packaging, ensuring the quality of the finished products.

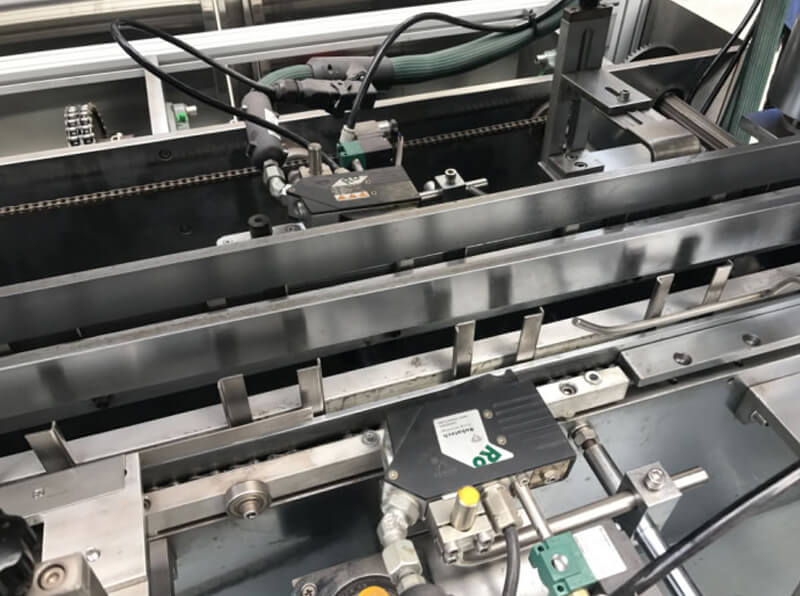

The entire mechanical operation is highly electronically synchronized, resulting in more coordinated and balanced operation.

This packaging machine can replace the labor of 15-20 people who would be required for traditional hand packing methods.

Product Gallery

Product Details

| Name | Description | |

|---|---|---|

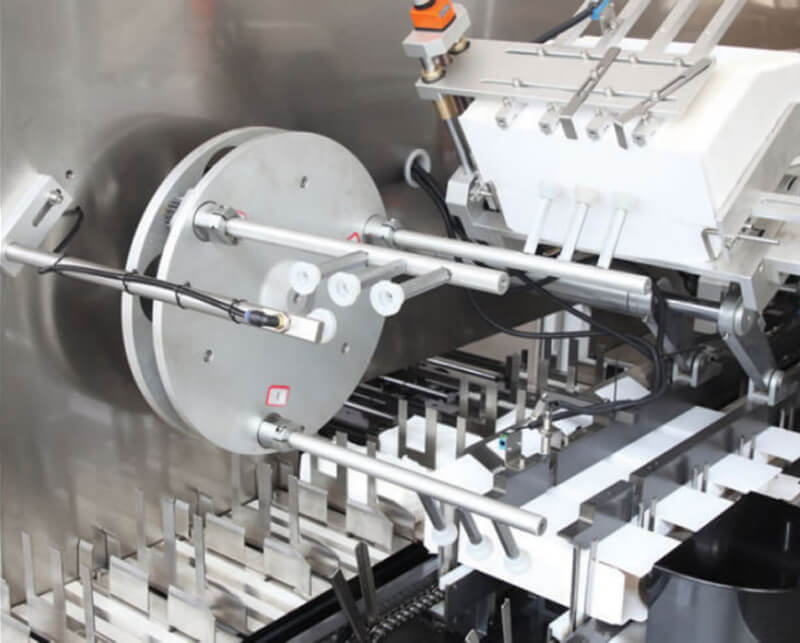

|

Robot Arm Pick Up Filling | Equipped with robot arm pick up filling |

|

Box Storage | Carton boxes loader,can be adjusted according to different box size. |

|

Box Pre-forming | There are three-head box opening device Faster and more stable |

|

Box Folding | Fold the flap for closing the boxes before sealing. |

|

Hot Melt Glue Sealing | It is an optional device ,can be customized as your request. |

|

Finshed Products Output | Fished product output from the conveyor. |

FAQs

Mostly used in food, pharmaceuticals, and consumer industry.

Mostly used in food, pharmaceuticals, and consumer industry.

Yes, definitely can be customized as your products.

It depends on your products size and the model of the machine.

Yes, cartooning machines are designed to be user-friendly and easy to operate.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!