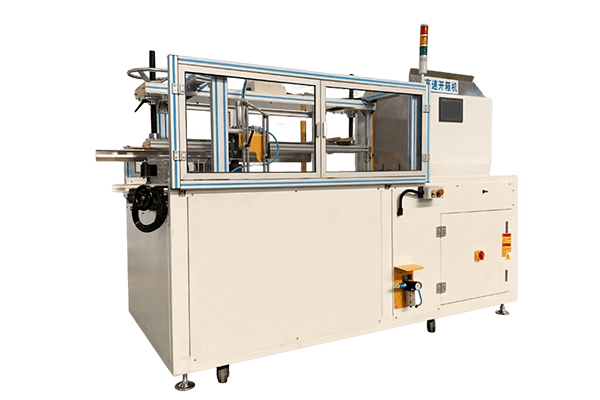

High Speed Carton Erecting Machine

High-speed carton erectors are designed to rapidly open and form cartons, allowing for a faster packaging process and increased production efficiency.

Technical Parameter

| Model | KX-25 |

| Speed | 0~25cartons/min |

| Carton Storage Quantity | 50pieces, carton thickness 1000mm |

| Applicable Carton Size | L 250-450 xW 150-350 x H 150-350mm |

| Applicable Tape Size | 48mm, 60mm, 72mm |

| Air Consumption | 6kg/cm2, 450NL/min |

| Power | 1KW,220V 50Hz |

| Machine Size | L2268xW1330xH1700mm |

| Weight | 990Kg |

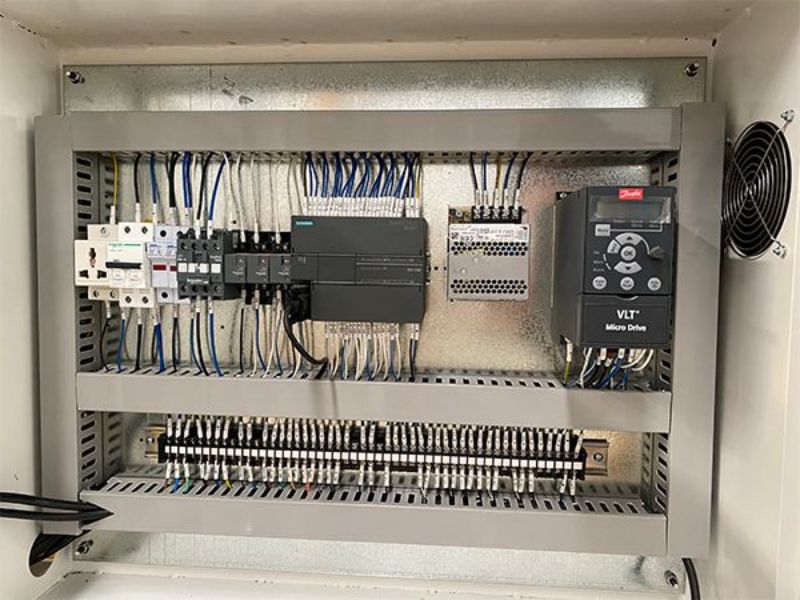

Electric Configuration

| PLC | Siemens/Germany |

| Touch Screen | MCGS |

| Motor | GPG/Taiwai |

| Cylinder | Airtac/Taiwan |

| Pressure reducing valve | FESTO |

| Sensor | SICK/Banner |

Machine Introduction&Features

The carton erector is a reliable and efficient machine that is designed to automatically open and form cartons of various sizes. This machine is capable of completing the entire packaging process, from box suction to folding and sealing, in one seamless operation. With its easy-to-use manual adjustment feature, changing carton sizes can be done quickly and easily, allowing for increased production efficiency.

The whole machine adopts CAM continuous system, keep the machine runs stably and durable.

Carton storage adopts horizontal, the cartons can be replenished at any time,no need to stop the machine.

With safety door switch protection device,the machine will be stopped once pen the door.

No carton warning and reminding.

No glue or tape warning function, automatically alarm and stop after the tape are used out.

The machine is designed to automatic sucking,forming the bottom.

Product Details

| Name | Description | |

|---|---|---|

|

Carton Storge | The carton storage adopts a horizontal arrangement, allowing for replenishment of empty paper boxes at any time without stopping the production process. |

|

Bottom Sealing | Automatically fold seal the bottom of carton via OPP tape. |

|

Touch Screen | The operation interface is simple, which is convenient for the operator to input data and adjust. |

|

High-performance Motor | The stable, powerful and durable motor is selected, which can work quickly and efficiently without interruption, with strong stability. |

|

Alarm Function | With tape and carton out of material alarm function, no material is automatically reminded, which is convenient for operators to add materials in time. |

FAQs

Our labeling machines are versatile and can label a variety of products, including round objects,suqare objects and objects with flat surface etc.

There are sleeve labeling machine,hot melt glue labeling machine,self-adhesive labeling machine and cold glue labeling machine,can meet your different labeling request.

Yes, our labeling machines are compatible with various container materials, including plastic, glass, and metal.

Yes, it can handle various label sizes and shapes, including wrap-around, front and back, and top and bottom labels.

Our labeling machines use advanced sensors and precision mechanics to ensure accurate label position, even on irregularly shaped containers.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!