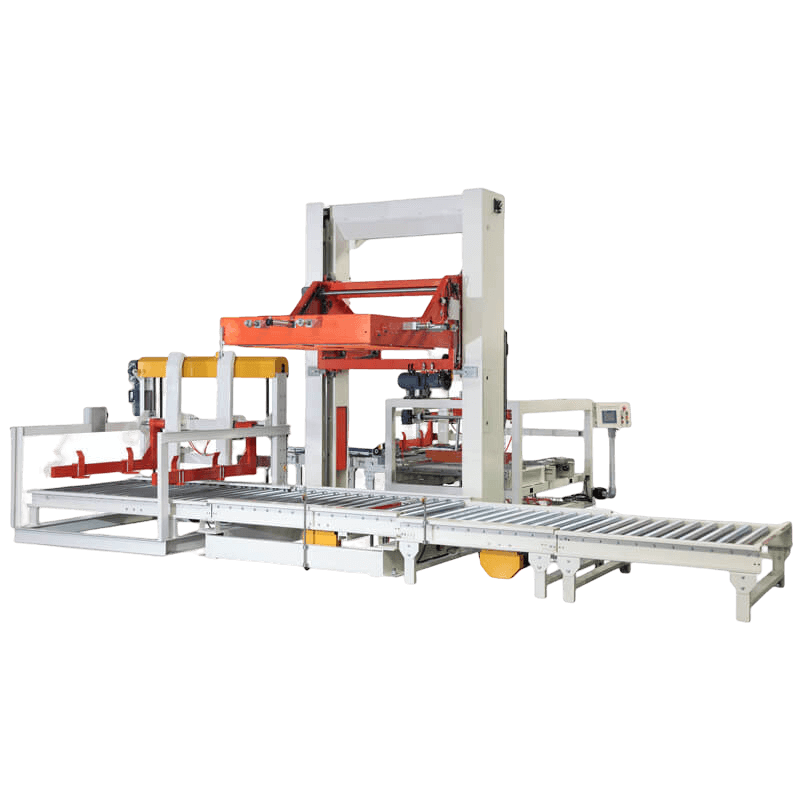

Low Level Palletizer

The low-level palletizer is a popular stacking equipment in the current market, which can meet the low to medium volume palletizing needs of businesses. It allows for the setting of the palletizing method and the number of layers according to the product requirements, and is suitable for a variety of products such as bagged, boxed, and film-wrapped items. Additionally, the palletizing effect of this equipment is flat, compact, and stable.

Technical Parameter

| Model | MD-L40 |

| Stacking Speed | 4-5cycles/min |

| Stacking Height Per Pallet | Case height*Layers/Stack |

| Max Load Per Layer | 150KG |

| MaX Load Per Pallet | 1500KG |

| Max Stacking Height | 1800mm |

| Eletric Power | 15.3KW |

| Compressed Air | 600L/min |

| Air Pressure | 0.6Mpa |

Electric Configuration

| PLC | Siemens |

| Touch Screen | Siemens |

| Sensor | SICK |

| Servo Motor | Panasonic |

| Frequency Inverter | Danfoss |

| Cylinder | SMC |

| Solenoid Valve | SMC |

| Emergency Stop | Schneider |

| Low Voltage Electric | Schneider |

| Driving Motor | SEW |

Machine Introduction&Features

The palletizer machine is designed to stack packaged products (such as cartons, bags, and drums) in a specific order onto empty pallets using a continuous series of mechanical actions.

This process improves the work environment and increases production efficiency, facilitating the bulk transportation of products.

The machine is specifically tailored to meet customer requirements for production processes and packaging, ensuring high-quality results.

It is controlled by a PLC and a touch screen, enabling easy and intelligent operation management that reduces labor costs and intensity.

It adopts a high-speed, stable, and space-saving design philosophy.

It uses a separated disc for stacking, which is faster and more space-efficient.

It has a high degree of versatility, allowing for quick adjustments and suitability for a wide range of product specifications.

The low-level palletizer is an ideal choice for efficient and flexible production.

Product Details

| Name | Description | |

|---|---|---|

|

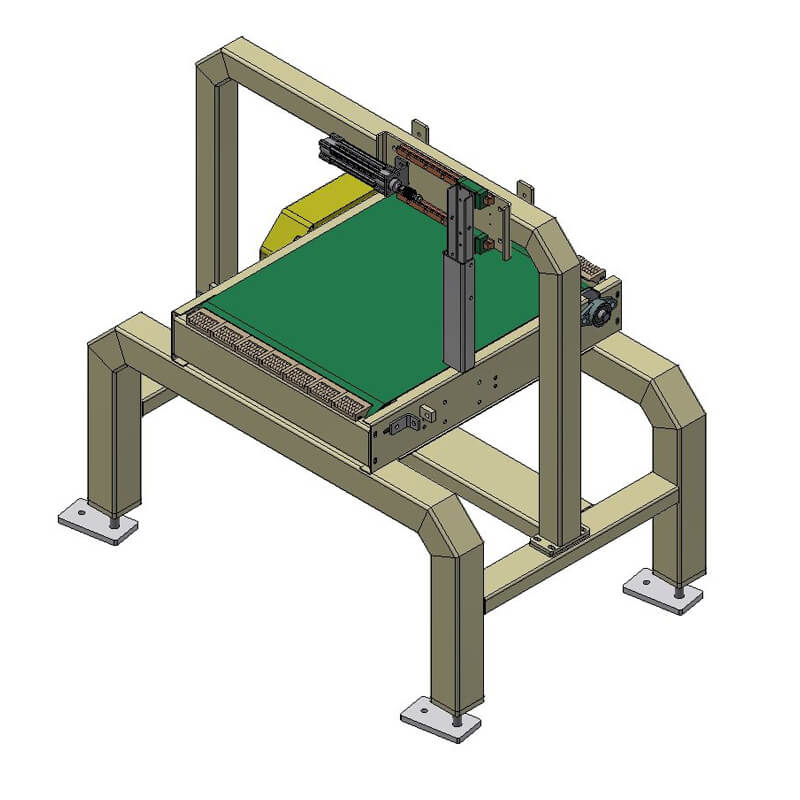

Accelerating Conveyor Belt | A conveyor belt system with two belts of different speeds, where the speed of the rear belt is more than twice that of the front belt. The speed difference can be adjusted using a frequency converter to control the distance between two boxes. This system is designed to create a gap between boxes by using the speed difference, which helps them turn more easily. |

|

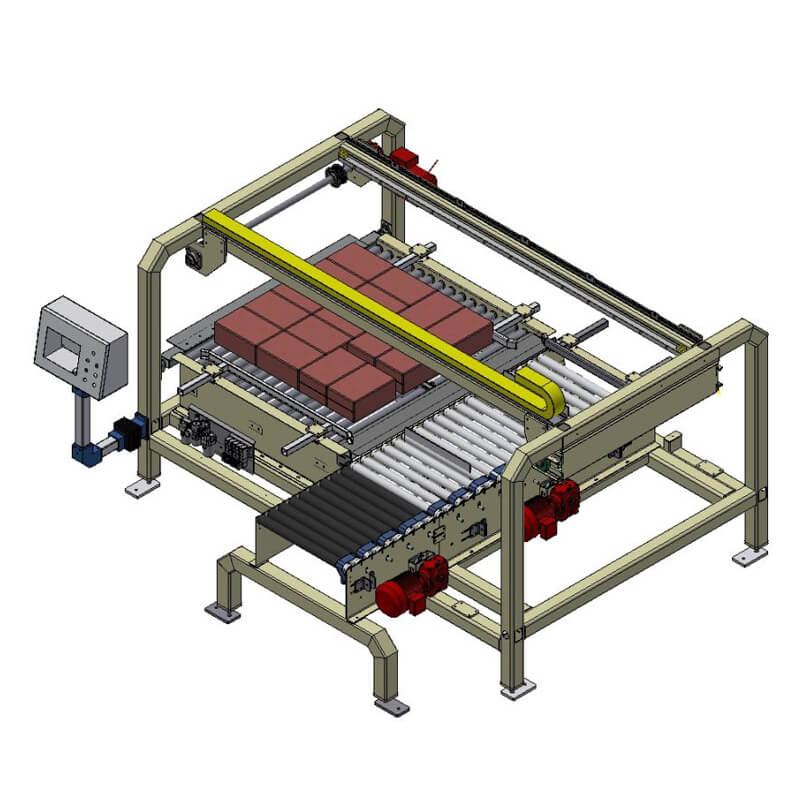

Sorting and Buffering System | This system uses rollers to transport cartons into the main palletizer unit. To better accommodate customer sorting requirements, an adjustable separator device has been added beneath the system, which can be freely adjusted using a handle to enable multiple sorting configurations. This provides convenient and efficient sorting options, ultimately improving productivity. |

|

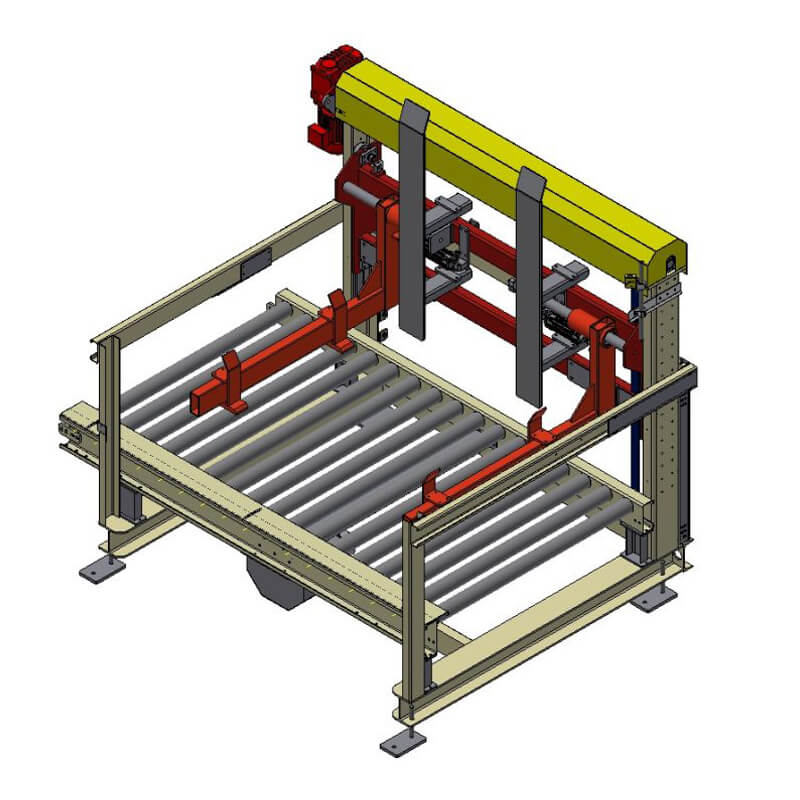

Pallet supply system | This mechanism can hold up to 10 empty pallets, which are sequentially and orderly placed onto a conveyor belt for empty pallets using a pneumatic cylinder. |

|

Case Steering Mechanism | This system enables the controlled rotation of case along a conveyor line. During straight-line movement, the bottom conveyor line moves at the same speed as the rear portion of the accelerating belt line. However, when a 90° rotation is required, a cylinder rapidly extends to block one side of the box, allowing for controlled rotation. |

FAQs

A palletizer is a type of machinery used to stack and arrange products onto pallets for shipment or storage.

Using a palletizer can improve efficiency, reduce labor costs, and minimize errors in the stacking and arranging process.

Palletizers can be used to stack boxes, bags, cans, and bottles etc.

Yes, It can be customized to accommodate specific stacking and arranging requirements such as size, shape, and material.

It is automatically arranging and stacking products onto pallets based on pre-determined patterns.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!