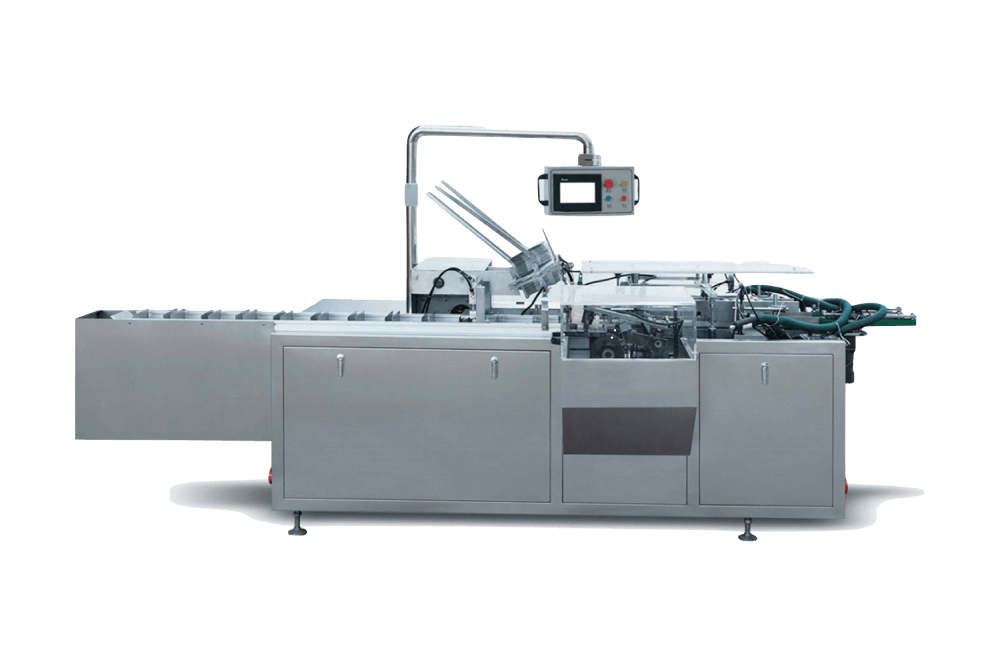

CSZ-100B Small Box Cartoning Machine

Specially designed for the small box packed goods which can pre-form the boxes, put the goods into the boxes,close and seal the box automatically. There are folding and glue sealing two options based on your packaging request.

Technical Parameter

| Model | CSZ-100B |

| Packing speed | 30-90cartons/min |

| Size of package | L(70-220)mm×W(14-90)mm×H(14-65)mm |

| Cardboard material | 250-350g/㎡ |

| Instruction material | 60-70g/㎡ |

| Instruction size (Unfold) | (80-150) x (90-170)mm |

| Instruction size (Fold) | (1-4) Fold |

| Motor power | 1.5kw |

| Power supply | 220V 50HZ |

| Minimum Air pressure | 0.6Mpa |

| Air consumption | 120-160L/min |

| Maximum noise | 80dB |

| Overall dimension | L3100mm×W1100mm×H1900mm |

| Weight | 1500Kg |

Electric Configuration

| PLC | CPIE-N30DT-D/Omron |

| PLC Extened Module | CPIE-C1F11/Omron |

| Touch Screen | NB7W-TW00B/Omron |

| Sensor | E3Z-D61/Sick |

| Frequency | 3G3JZ-A4015/Omron |

| Relay | MY2 NJ24V/Omron |

| Button | XB2/Schneider |

| Emergency Stop | ZB2 BC4D/Schneider |

| Electromagnetic Valve | 4V210-08/Airtac |

| Pressure Regulator Valve | BFR-2000/Airtac |

| Proximity Switch | TL-Q5MC1/Omron |

| AC contactor | LC1E3210M5N/Schneider |

| Air switch | 3P32A 1P6A/Schneider |

| Vaccum Sounder | ABM20-C/SMC |

Machine Introduction&Features

The CSZ-100B cartoning machine is an automated solution for packaging items in the pharmaceutical, food, and cosmetics industries. It can fold booklets, open cartons, pack objects, print batch numbers, seal packages, and reduce waste without manual labor. Equipped with a PLC and electro-optical tracking system, the machine shuts down and indicates any problems. It is certified to GMP standards and can handle different materials. It can be paired with blister pack cartoning equipment for maximum efficiency.

This cartoning machine boasts an automated delivery system that efficiently folds instruction booklets, opens cartons, packs objects and instructions, seals packages, and eliminates waste.

The cartoning machine is very easy to operate. 1-2 operators is enough, as most of the process is fully automatic.

Controlled by a PLC with a touch screen interface, making it user-friendly and easy to operate.

An electro-optical tracking system helps to save materials, while an empty package detection system ensures that only properly filled packages are sent out.

Adjusting the machine for different product sizes is easy and quick, without the need for mold changes.

Can be euipped with a aluminum plastic packaging machine, flow-pack wrapping machine, 3D packaging machine, bottling line, filling machine, labeling machine, inkjet printer, online weighing instrument etc.

Widely used in stationery packaging,Pharmaceutical,Food,Daily necessities packaging etc.

Product Details

| Name | Description | |

|---|---|---|

|

Automatic Feeding System | Automatically feeding goods into the downstream unit in an efficient manner. |

|

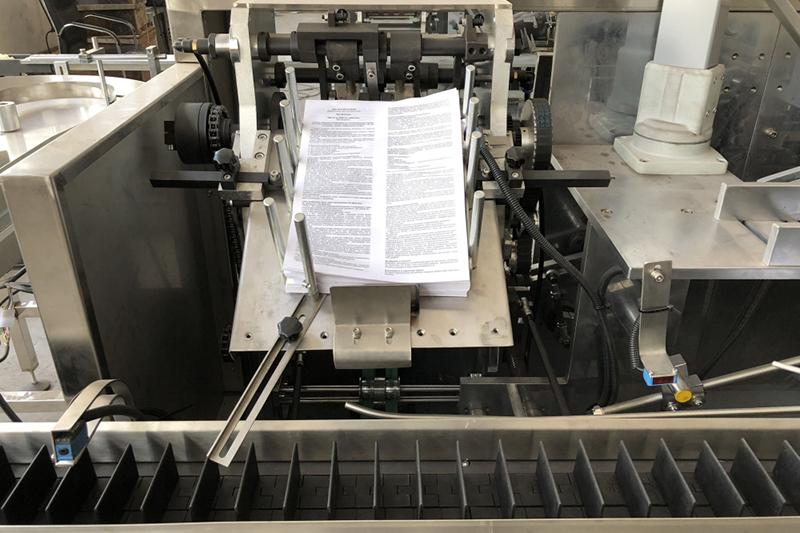

Instruction Folding Device | Folding the instruction paper sheets which is under the combined action of vacuum and compressed air.The folded paper sheet will be placed in position for cartoning by feeding chain. |

|

Carton Storage | The carton store has a board that can move to adjust the package length. Both the front and back frame are connected by a slot hole in order to fit different packaging widths. |

|

Sensor | German brand SICK infrared protector is able to detect and track the whole system automatically making sure this packaging machine runs normally. |

|

Pushing Device | It pushes products and instruction booklets into cartons. |

|

Unqualified Products Rejection | This part conveys the completed packages and eliminates unqualified ones. It quickly pushes packages off the conveyor to prevent them from being broken or damaged by chains. |

FAQs

Mostly used in food, pharmaceuticals, and consumer industry.

Mostly used in food, pharmaceuticals, and consumer industry.

Yes, definitely can be customized as your products.

It depends on your products size and the model of the machine.

Yes, cartooning machines are designed to be user-friendly and easy to operate.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!