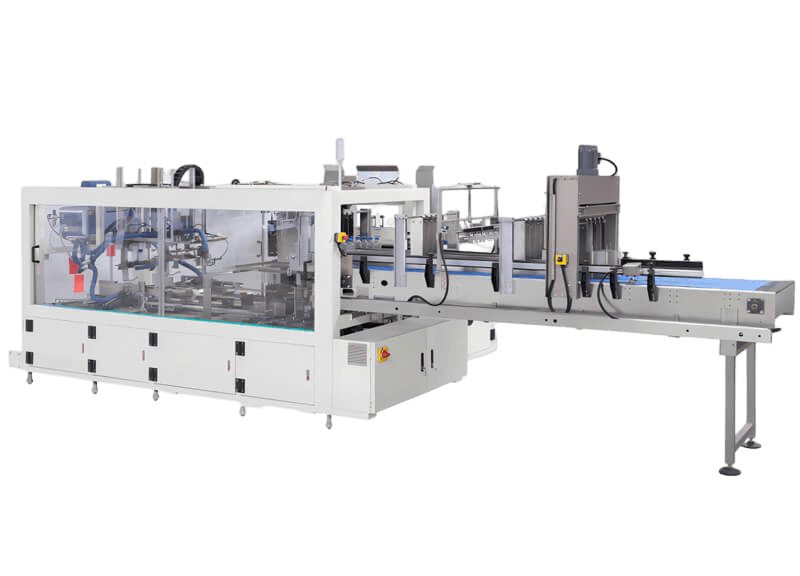

Wrap Around Case Packer

This model is designed to work with PET, PP, glass bottles, and can easily switch between different bottle types. Additionally, it is also suitable for various types of packaging combinations. Our carton packaging machine can adapt to different types and shapes of bottles and can easily switch between them during the production process. Furthermore, it can handle different packaging formats, allowing for the production of a variety of product combinations.

Technical Parameter

| Model | GB-25 |

| Speed | 20-22pcs/min |

| Power Supply | 8KW |

| Control | AC 220V, 1P, 50HZ & DC24V |

| Air Pressure | 4-5kg/cm2 |

| Air Consumption | 150NL/min |

| Overall Dimension | L6070mm*W2800mm*H2006mm |

| Weight | 3000kg |

Electric Configuration

| PLC | INOVANCE |

| Touch Screen | INOVANCE |

| Sensor | SICK |

| Hot Melt Glue Machine | USA Nordson |

| Main Servo Motor | INOVANCE |

| Cylinder | SMC |

| Solenoid Valve | SMC |

| Emergency Stop | Schneider |

| Reducer | U-can |

Machine Introduction&Features

The Case wraparound machine is used for packing bottles that come out of the filling machine into cartons in a wraparound fashion, which improves production efficiency and satisfies customer packaging requirements. The bottles are transported by a conveyor and are inspected and arranged according to a programmed process. Once the complete carton arrangement is finished, the cardboard supplying mechanism sends the cardboard into the machine, and the bottle dropping mechanism drops the bottles into the cardboard. The cardboard folding mechanism then folds the cardboard, applies glue, and seals it step by step. Finally, the formed carton is sent out of the machine by the roller, which improves production efficiency and enables full automatic manless production.

The conveyor belt is made of stainless steel 304.

The frame and base of the machine are made of A3 steel.

The color of the paint used for the equipment will be determined by the user, while the color of externally purchased parts will follow the standard color of the equipment supplier.

The control panel will use touch screen controls.

The machine has a single production capacity of 20-22 boxes per minute.

The hot melt glue system used in the machine is produced by Nordson in the United States.

The time from gluing the case to bonding is less than 0.7 seconds, while the time from bonding to case discharge (i.e., the time for the external force to press the case to solidify the hot melt glue) is more than 2 seconds.

The case sealing process is smooth and gentle, with no broken bottles.

The sealed case are firm and tight, with no looseness.

During the packaging process, the equipment should not damage the product packaging.

Product Details

| Name | Description | |

|---|---|---|

|

Product Feeding Conveyor | The bottles, cans, or containers will be separated and inspected on this conveyor. |

|

Automatic Cardboard Supplying System | This system is located on the side of the main packing machine and is designed to store carton cardboard. The vacuum suction disk pulls the cardboard into the guide slot, and the belt conveyor transports it into the main packing machine for further processing. |

|

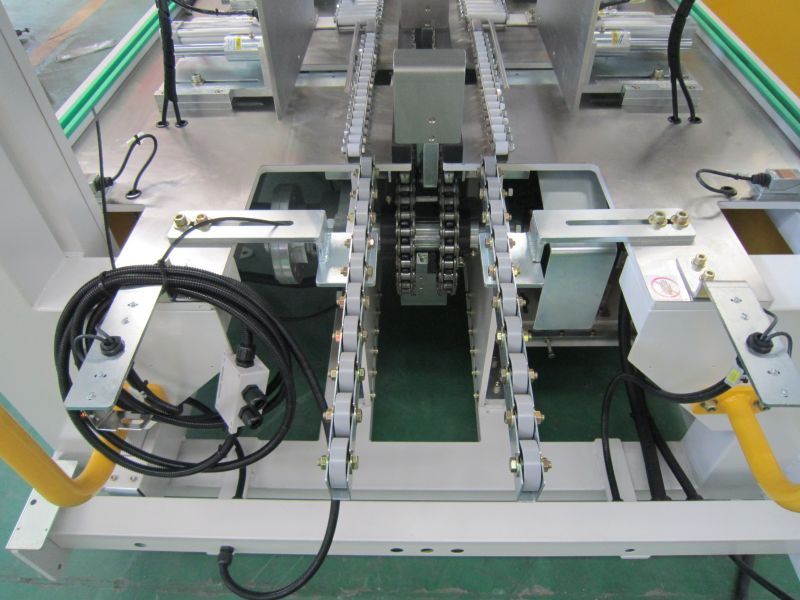

Automatic Bottle Dropping System | This system is specifically designed to streamline the process of separating and dropping individual bottles within a carton unit, resulting in a highly efficient and automated production line. |

|

Hot Melt Glue Spraying System | The glue machine, made by Nordson in the United States, applies hot melt adhesive onto the paper box for the final sealing process. |

|

Lateral Carton Pressing Mechanism | The mechanism is a device used to apply pressure to the sides of a cardboard box in order to shape it appropriately. |

|

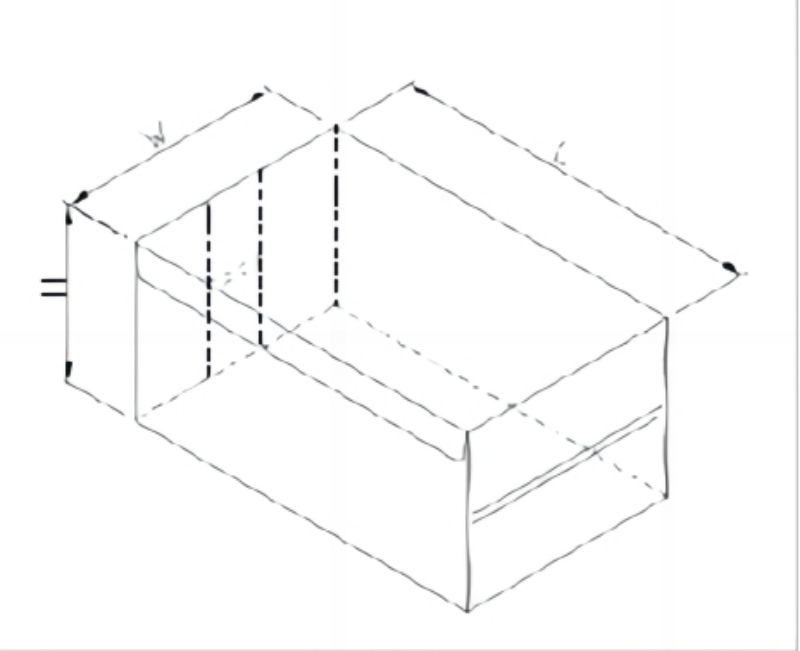

Applicable Carton Specification | Max=450mm(L) x 300mm(W) x 330mm(H) Min=260mm(L) x 165mm(W) x 90mm(H) |

FAQs

There are drop type case packer, wrap-around case packer, and grip type case packer.

Yes, it can be customized according to your product sizes and shapes.

Increased efficiency, productivity, and consistency in the packaging process,reduce labor costs and minimize the risk of product damage during packaging.

Food and beverage, pharmaceuticals, and consumer industry.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!