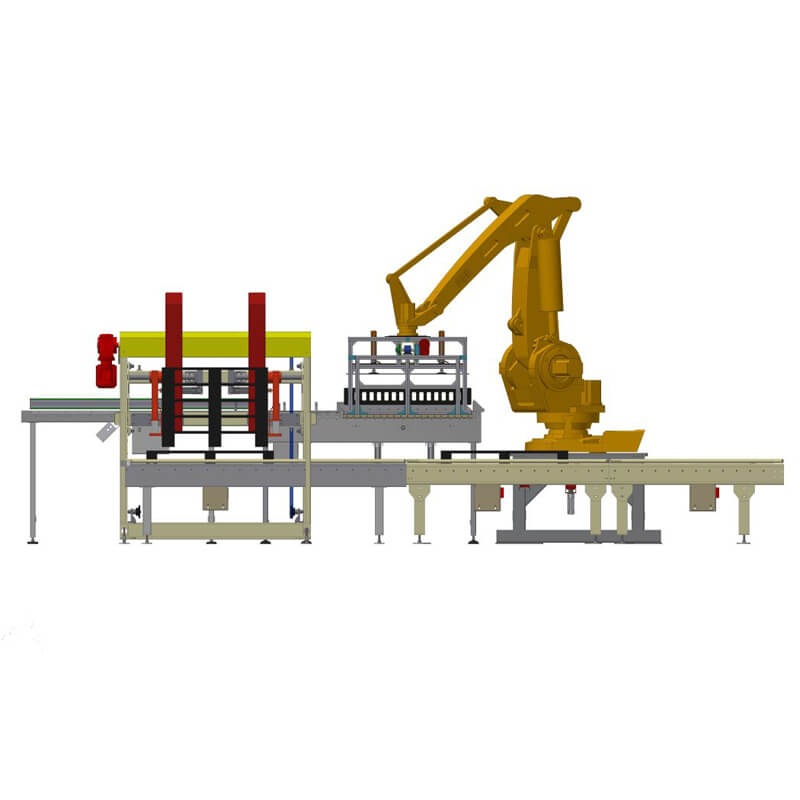

Robotic Palletizer

Robot palletizing is the automated process of stacking packaged products onto empty pallets in a specific order, facilitating the transport and handling of large quantities of products more efficiently. It reduces the need for manual labor, minimizes the risk of worker injury, and can be customized to suit various industries for safe and secure transport of products.

Technical Parameter

| Model | MD-R40 |

| Speed | 12-15second/cycle |

| Max Load Weight Per Pallet | 1500KGS |

| Max Stacking Height | 1600mm |

| Power Consumption | 15KW |

| Air Pressure | &bar |

| Voltage | 380V 50HZ 3Phrase |

| Air Consumption | 400L/min |

| Weight | 11000KG |

| Overall Dimension | L13600mm*W9500mm*H4300mm |

Electric Configuration

| PLC | Siemens |

| Touch Screen | Siemens |

| Sensor | SICK |

| Servo Motor | Panasonic |

| Frequency Inverter | Danfoss |

| Cylinder | SMC |

| Solenoid Valve | SMC |

| Emergency Stop | Schneider |

| Low Voltage Electric | Schneider |

| Driving Motor | SEW |

| Robot | ABB |

Machine Introduction&Features

Our robot palletizer is used to automatically transfer, sort, and stack formed cartons for packaging. The cartons are sorted and pushed into place by an automated conveyor system, while the pallets are transported to a specific location. With the assistance of a robot, the boxes are stacked in preparation for storage. Advanced sensing and control systems can optimize this process to improve accuracy, speed, and efficiency.

The system uses a PLC programmable computer controller, photoelectric switches, travel switches, pneumatic control, and other control systems to achieve precise mechanical movements and easy operation.

The palletizing system uses high-precision robots for operation, which are stable in action, have fewer malfunctions, and are durable.

The system has a simple structure and fewer components, resulting in a lower failure rate for components, reliable performance, easy maintenance, and fewer spare parts required in inventory.

Product Details

| Name | Description | |

|---|---|---|

|

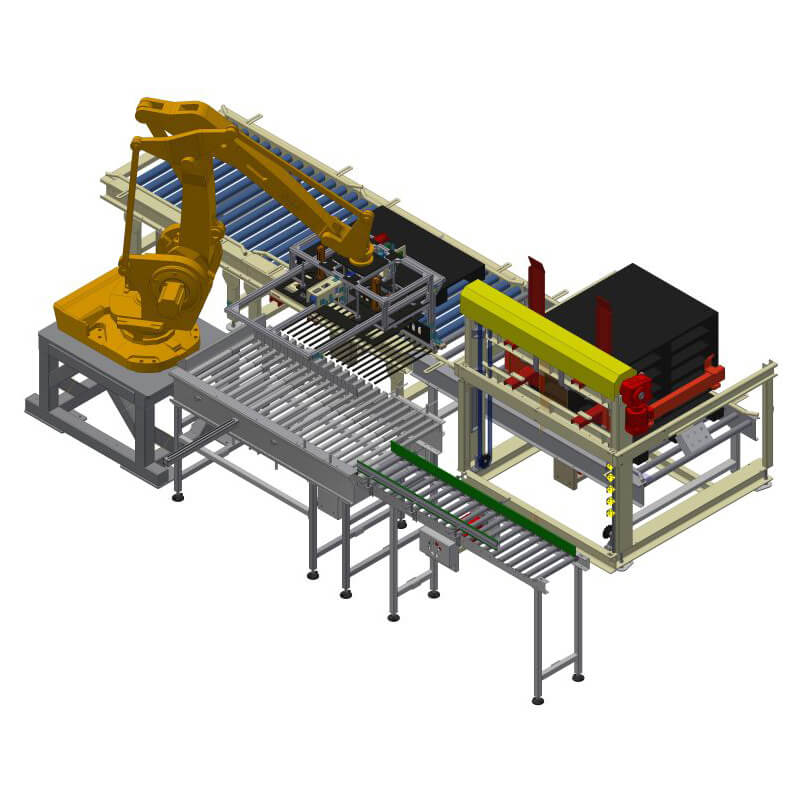

Robot Main Machine | We choose robot brands for a robotic palletizing system based on different customer budgets and production line requirements |

|

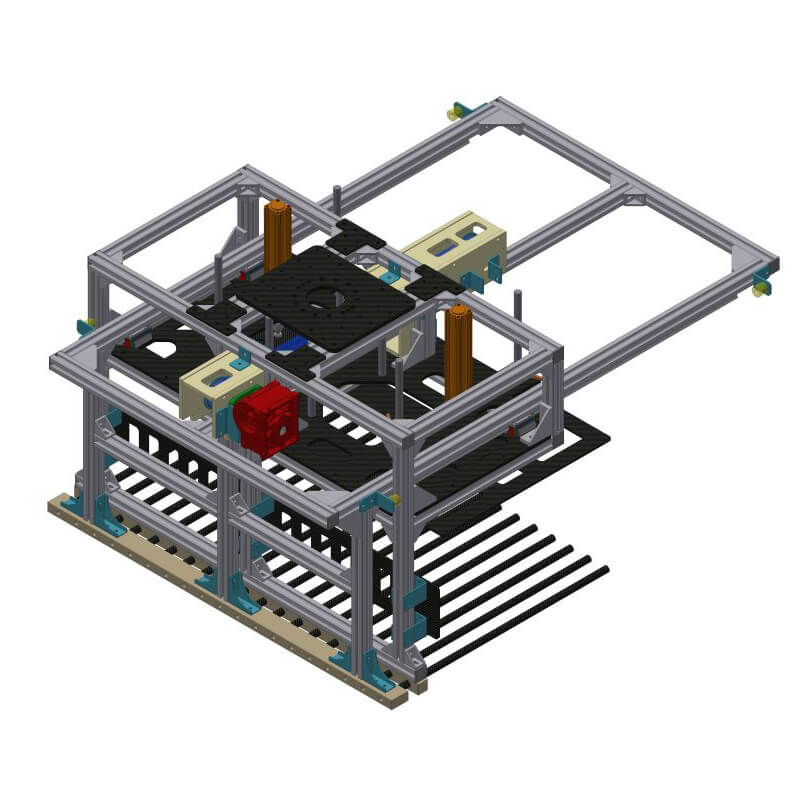

Product Gripper | Product grippers for a robot palletizing system is to carefully analyze the customer's product and speed requirements and choose a gripper type that can handle the product safely and efficiently, while also meeting the customer's budget constraints. |

|

Gripping Platform | the gripping platform of a robotic palletizing system using a stainless steel roller conveyor is to carefully consider the customer's product and speed requirements and design a platform that can handle those requirements while integrating effectively with the overall system. |

|

Robot Palletizing Work Flow | The workflow of a robotic palletizing system involves manually placing empty pallets, transporting products to the gripping position, arranging the products onto the pallet, and removing the completed pallet using suitable equipment. |

FAQs

A palletizer is a type of machinery used to stack and arrange products onto pallets for shipment or storage.

Using a palletizer can improve efficiency, reduce labor costs, and minimize errors in the stacking and arranging process.

Palletizers can be used to stack boxes, bags, cans, and bottles etc.

Yes, It can be customized to accommodate specific stacking and arranging requirements such as size, shape, and material.

It is automatically arranging and stacking products onto pallets based on pre-determined patterns.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!