Pick And Place Case Packer

This case packing machine is primarily designed for automatically packing bottles into case, and is suitable for the bottle packaging processes in beer and beverage production lines, as well as in other industries. It provides optimized solutions for efficient and reliable bottle packing.

Technical Parameter

| Model | ZX-20 |

| Speed | 0-25pcs/min |

| Power Supply | 3.5KW |

| Working Pressure | Cylinder 0.3Mpa |

| Air Pressure | 0.5Mpa |

| Air Consumption | 600NL/min |

| Overall Dimension | L1500mm*W1250mm*H1840mm |

| Weight | 3000kg |

Electric Configuration

| PLC | Siemens |

| Touch Screen | Siemens |

| Sensor | SICK |

| Drive Motor | Omate |

| Frequency Inverter | Schneider |

| Cylinder | Airtac |

| Solenoid Valve | Airtac |

| Emergency Stop | Schneider |

| Low Voltage Electric | Schneider |

Machine Introduction&Features

This carton packaging machine features a PLC-controlled main drive system with a user-friendly interface that allows for stepless speed regulation and easy operation. Its compact and efficient design provides a high degree of automation.

Additionally, the machine is equipped with oil-free pneumatic components and most of its moving parts are designed to operate without oil lubrication, which helps reduce overall maintenance costs. The auto packingmachine is primarily used in industries such as food and medicine, daily necessities, industrial products, textiles, and cosmetics.

The machine runs smoothly with a motor or cylinder that has a braking system to drive the box-loading mechanism. Its unique track structure enables bottles to be lifted and lowered with precision and stability.

The machine achieves high production efficiency by starting and stopping slowly and moving rapidly in between, thereby reducing non-working time and enhancing productivity.

The machine is easy to operate since it is fully automated and synchronized with the entire production line in terms of speed control.

The machine's advanced technology, simple mechanical structure, and reliable pneumatic and electronic control systems make it a rational and efficient machine.

The machine is equipped with various safety features, such as protective covers, safety nets, and photoelectric safety protection devices that automatically stop the machine if an operator enters a dangerous area.

The machine is designed to meet strict hygiene standards as it operates with low noise and utilizes oil-free pneumatic components, thereby preventing oil pollution.

The machine operates reliably by using a gripper head to grab and release bottles with precision. Its mechanical, pneumatic, and electronic control systems ensure that bottles are accurately placed into boxes.

Product Details

| Name | Description | |

|---|---|---|

|

Bottle Gripper | During operation, the gripper fingers of the grab-type carton packing machine will grip the products and then transfer them to the designated location of the packaging carton. The gripper can be adjusted according to different sizes of grips and different numbers of gripper fingers to accommodate products of different shapes and sizes, as well as different speeds. |

|

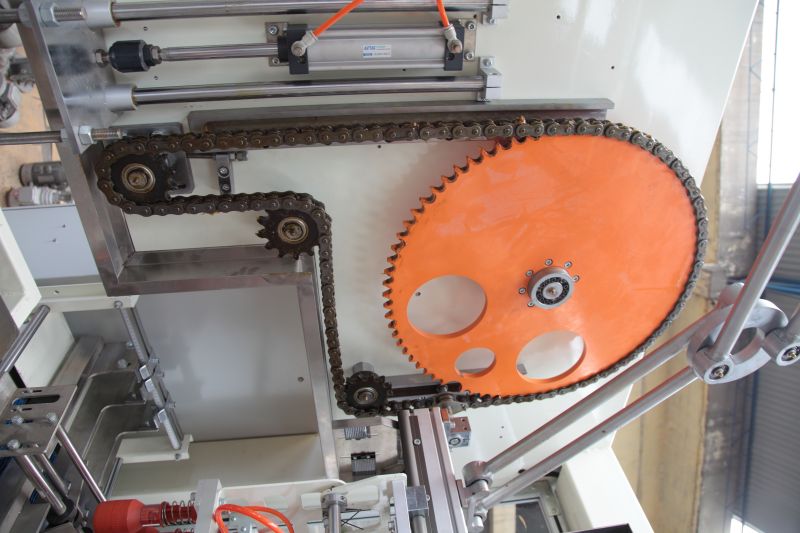

Sprocket Group | The case packer sprocket group is designed with an RS80 chain drive, providing a high carrying capacity and stable transmission. The bilateral symmetrical design further enhances the stability and balance of the system. |

|

Calibration Mechanism | The case packaging machine is equipped with a calibration mechanism that is designed to facilitate easier and more precise adjustments for customers. |

FAQs

There are drop type case packer, wrap-around case packer, and grip type case packer.

Yes, it can be customized according to your product sizes and shapes.

Increased efficiency, productivity, and consistency in the packaging process,reduce labor costs and minimize the risk of product damage during packaging.

Food and beverage, pharmaceuticals, and consumer industry.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!