High Level Palletizer

The High-Level Palletizer is an automated mechanical system that stacks packaged products (such as cartons, film-wrapped items, plastic boxes, bags, and drums) in a predetermined sequence onto corresponding empty pallets. This system is designed to improve the working environment on the production line, enhance productivity, and facilitate the transportation and handling of batches of products. It is suitable for use in various industries such as beer, bottled water, beverages, grains and oils, cosmetics, pharmaceuticals, and food production lines.

Technical Parameter

| Model | HP-60 |

| Speed | 60-80packages/minute |

| Power Supply | around 16.5KW |

| Min Working Pressure | 5-6Bar |

| Voltage | 380V 50HZ 3PH |

| Stacking Speed | 3-4.5Cycle/minute |

| Stacking Height Per Layer | Case*Layer/Pallet |

| Max Load Weight Per Layer | 150KGS |

| Max Load Weight Per Pallet | 1500KGS |

| Max Stacking Height | 1800mm |

| Air Consumption | 330NL/minute |

| Overall Dimension | L9900mm*W6900mm*H3800mm |

| Weight | 9000KGS |

Electric Configuration

| PLC | Siemens |

| Touch Screen | Siemens |

| Sensor | SICK |

| Servo Motor | Panassonic |

| Frequency Inverter | Danfoss |

| Pneumatic Part | Festo |

| Drive Motor | SEW |

| Emergency Stop | Schneider |

| High Voltage Electric | Schneider |

Machine Introduction&Features

High-level palletizer is an packing equipment that can automatically stack packaged boxes, film-wrapped items, plastic containers, and other products onto pallets.

Specifically, it uses an accelerated carton box separation conveyor to evenly space out products, then groups them according to stacking requirements by turning them 90 degrees or maintaining their original direction.

After pre-stacking at the pre-stacking station, the pushing mechanism pushes the products onto the transition plate.

Then, the lifting mechanism lifts the transition plate to the stacking position and stacks one layer at a time, moving down to the next layer until the stacking is complete. Finally, the stacked pallets are lowered to a conveyor at the same height for forklift retrieval.

The High-Level Dragon Gate Palletizer is designed to have stable and smooth movements when stacking packaged products. This is achieved through the use of linear guides with sliders, resulting in a noise-free operation.

The palletizer allows for easy switching and adjustment of different products, making it a versatile tool for production lines.

The High-Level Dragon Gate Palletizer can be used in a variety of industries, including beer, bottled water, beverages, grains and oils, cosmetics, pharmaceuticals, and food production lines.

The palletizer has a high production capacity, allowing for the stacking of large quantities of products at a time.

The palletizer can arrange products in various stacking configurations, providing flexibility and adaptability to different production needs.

The safety protection device made of carbon steel sandblasted paint, organic glass, and protective netting meets national standards.

The safety protection device can automatically shut down and alarm in the event of equipment abnormalities.

The main palletising machine frame is made of carbon steel sandblasted paint.

Product Details

| Name | Description | |

|---|---|---|

|

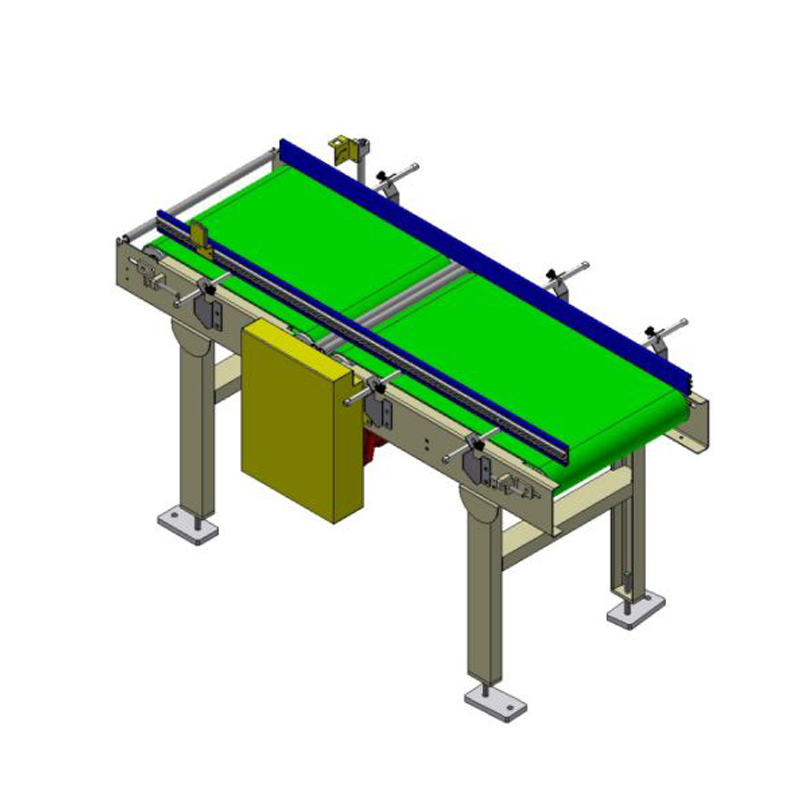

Accelerating Conveyor Belt | A conveyor belt system with two belts of different speeds, where the speed of the rear belt is more than twice that of the front belt. The speed difference can be adjusted using a frequency converter to control the distance between two boxes. This system is designed to create a gap between boxes by using the speed difference, which helps them turn more easily. |

|

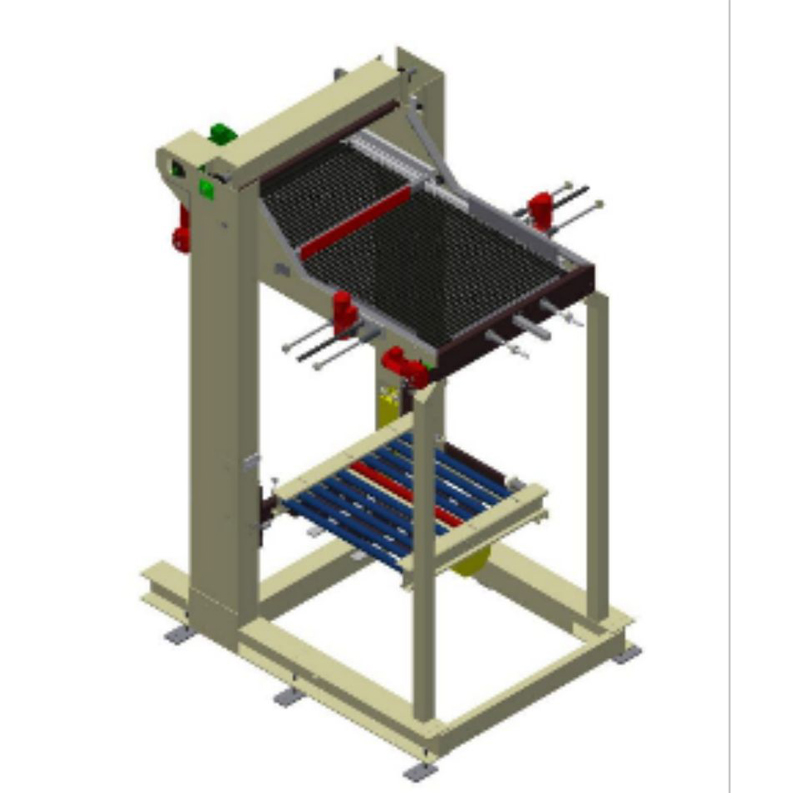

Palletizer Main Machine | The main body of the palletizing machine consists of a framework and lifting power system. Its function is to organize loose products and compact them by layering them onto the lifting platform through a sliding mechanism. The lifting platform mechanism is equipped with a powered roller conveyor. |

|

Pallet supply system | This mechanism can hold up to 10 empty pallets, which are sequentially and orderly placed onto a conveyor belt for empty pallets using a pneumatic cylinder. |

|

Case Steering Mechanism | This system enables the controlled rotation of case along a conveyor line. During straight-line movement, the bottom conveyor line moves at the same speed as the rear portion of the accelerating belt line. However, when a 90° rotation is required, a cylinder rapidly extends to block one side of the box, allowing for controlled rotation. |

FAQs

A palletizer is a type of machinery used to stack and arrange products onto pallets for shipment or storage.

Using a palletizer can improve efficiency, reduce labor costs, and minimize errors in the stacking and arranging process.

Palletizers can be used to stack boxes, bags, cans, and bottles etc.

Yes, It can be customized to accommodate specific stacking and arranging requirements such as size, shape, and material.

It is automatically arranging and stacking products onto pallets based on pre-determined patterns.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!