Drop Type Case Packer

Our drop-type automatic case packer machine is an effective solution for streamlining transportation and packaging processes by packing finished products into cases with a predetermined arrangement

Technical Parameter

| Model | ZX-15 |

| Speed | 12-15pcs/min |

| Power Supply | 3KW |

| Working Noise | less than 75db |

| Applible Container | Round container or Square Container |

| Air Consumption | around 0.9m3/minute |

| Overall Dimension | L5000mm*W1000mm*H1650mm |

| Weight | 1200kg |

Electric Configuration

| PLC | Schneider |

| Touch Screen | Schneider |

| Sensor | SICK |

| Gear Motor | ECERGEAR |

| Frequency Inverter | Schneider |

| Cylinder | Airtac |

| Solenoid Valve | Airtac |

| Emergency Stop | Schneider |

| Low Voltage Electric | Schneider |

Machine Introduction&Features

The fully automated drop-type case packing machine, also known as a falling type case packing equipment, is capable of precisely positioning rows of bottles over a cardboard case and automatically dropping the rows of packaged bottle into the case through a positioning device based on packing requirements. This pack machine is particularly suitable for packing irregularly-shaped bottles, large-volume containers, and bagged products. It is an ideal solution for fully automated packing of various products such as edible oils, beverages, mineral water, and detergents, among others.

Our drop carton packaging machines deliver reliable performance, with high-quality and visually appealing packaging.

Use internationally renowned components, to make our machines easy to operate and maintain.

Our control system ensures smooth operation and protects against malfunctions or accidents.

The machines are highly portable and suitable for a wide range of products.

They use advanced technology for automation and user-friendly interfaces.

Customized non-standard designs are available, and safety features include automatic shut-off in case of missing bottles.

Pneumatic sorting mechanisms arrange products as specified.

Product Details

| Name | Description | |

|---|---|---|

|

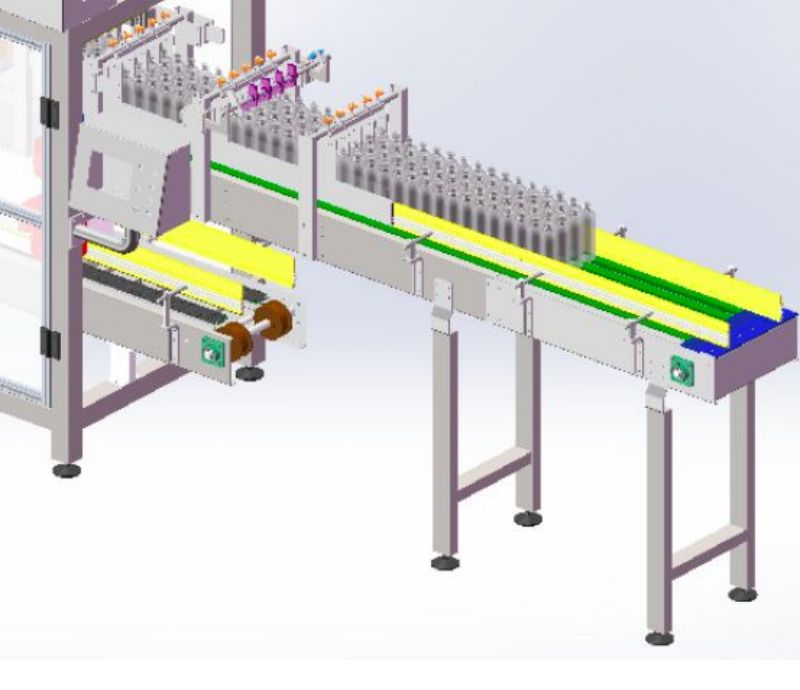

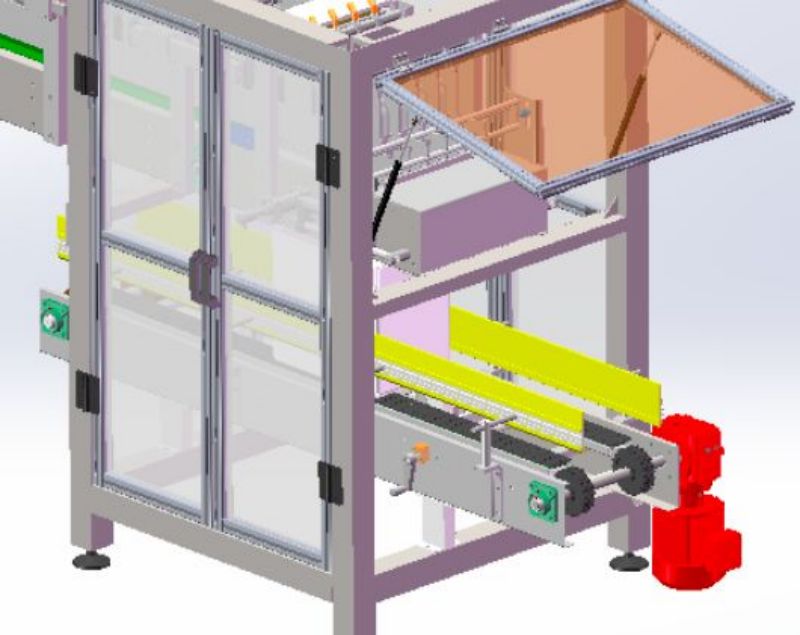

Bottle Conveying Group | The mechanism serves to organize and align the products transported along the conveyor, ensuring they are neatly positioned for subsequent processing at the bottle drop workstation. Essentially, the device streamlines the movement of products along the production line, optimizing workflow and productivity. |

|

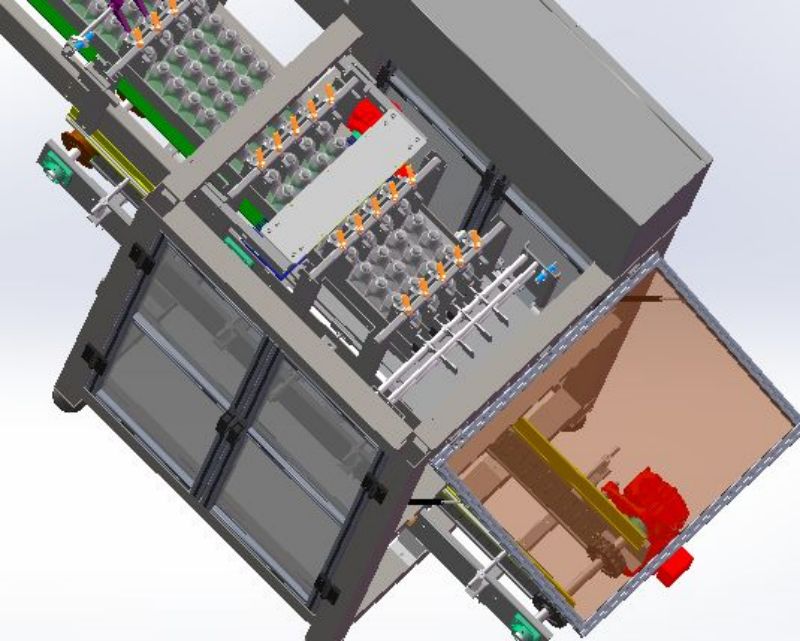

Bottle Pushing Group | This mechanism is to facilitate the seamless transfer of products from the bottle-dropping workstation into the bottle-receiving group. When the product reaches the designated work position, the device is activated to carefully and accurately push it into the container. By ensuring consistent and reliable product placement, the bottle pushing group helps to optimize the bottling process, reducing errors and improving overall efficiency. |

|

Case Packer Drawing | A gravity-based drop case packer relies on gravity and a track system to pack products into case quickly and efficiently. Its simple design allows for easy maintenance and fast operation. |

FAQs

There are drop type case packer, wrap-around case packer, and grip type case packer.

Yes, it can be customized according to your product sizes and shapes.

Increased efficiency, productivity, and consistency in the packaging process,reduce labor costs and minimize the risk of product damage during packaging.

Food and beverage, pharmaceuticals, and consumer industry.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!