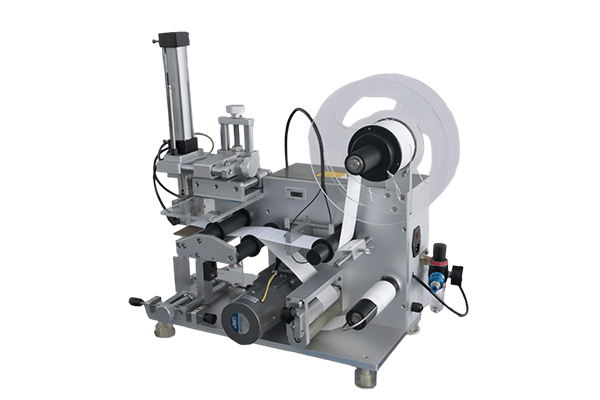

Semi-auto Flag Labeling Machine

This flag labeling machine can handle a variety of materials including round wires, flat wires, round tubes, flag shapes, lollipops, flower branches, and optical cables.

Technical Parameter

| Model | BGJ-C50 |

| Labeling speed | 20-40pcs/min |

| Labeling material | Self-adhesive sticker, opaque or transparent label |

| Applicable product diameter | 1-8mm |

| Applicable label size | L:5-40mm,W:20-60mm |

| Labeling precision | +/-1mm(exclude the product and label deviation) |

| Power supply | 220V 50/60HZ |

| Overall dimension | L850mm×W340mm×700mm |

| Weight | 36KG |

Electric Configuration

| Sensor | D10BFP/Banner |

| Labeling Motor | 2S86Q-030B8/KINCO |

| Labeling Motor Drive | 2M860/KINCO |

| Converyor Motor | D63B14-0.18KW+FB/Li-ming |

| Frequency converter | S800-2S0.4G/SAVCH |

| Emergency Stop | XB2-BS542/Omron |

| Relay | LY2N-J 24VDC/Omron |

Machine Introduction&Features

Flag labeling is a process that involves applying labels around cylindrical or small items like cables, hoses, wires, tools, hardware, or medical devices. To streamline this process and ensure consistent accuracy, a flag applicator can be used. This device efficiently wraps labels around fine or smaller cylindrical items, including cables, wires, tubes, hoses, and medical devices, at a significantly faster rate than manual application.

Mostly used for cables,wires and other small cylindrical objects.

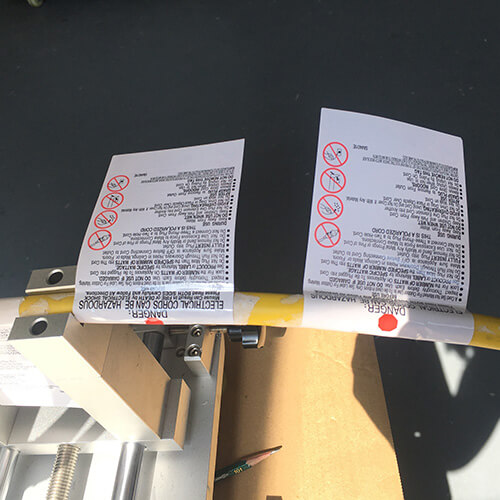

Used to apply labels in a 'flag' format, where the two ends of the label are joined to form a flag section on the product.

The format is commonly used to allow extended label information to that which would be possible if the label was placed only on the product itself.

The structure is small and occupies a small area, which is convenient for equipment movement and placement.

Product Gallery

Product Details

| Name | Description |

|---|---|

| Label Roll Holder | Composed of label supply plate and label roll, used to hold rolls of label material. |

| Cylinder For Labeling | There are two cylinder system,one is for fix the position of product,another automatically moves up and down to complete the labeling action. |

| Main Machine Adjustable Device | Used to adjust the front and rear position of the main machine for folding effects. |

| Air Source Processor | A three-in-one air source filter that regulates air pressure and filters out moisture from the air source. |

| Photoelectric Detection Device | Detects and recognizes gaps between labels to trigger motor reset and stop. |

| Paper Collection Mechanism | Composed of paper collection tray, paper collection axle, and other parts, used to collect waste paper after labeling. |

FAQs

Our labeling machines are versatile and can label a variety of products, including round objects,suqare objects and objects with flat surface etc.

There are sleeve labeling machine,hot melt glue labeling machine,self-adhesive labeling machine and cold glue labeling machine,can meet your different labeling request.

Yes, our labeling machines are compatible with various container materials, including plastic, glass, and metal.

Yes, it can handle various label sizes and shapes, including wrap-around, front and back, and top and bottom labels.

Our labeling machines use advanced sensors and precision mechanics to ensure accurate label position, even on irregularly shaped containers.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!