Double-head Sleeve Labeling Machine

Automatic double head sleeve labeling machine can sleeve label for bottle body and cap at the same time.

Technical Parameter

| Model | TB-D150/D250/D350 |

| Labeling speed | 150BPM*2/250BPM*2/350BPM*2 (500ml) |

| Labeling material | PVC,PET,OPS |

| Applicable diameter of bottle | Ø28- Ø125mm |

| Applicable height of bottle | 30mm-280mm |

| Applicable label length | 30-250mm |

| Applicable label thickness | 0.027mm-0.13mm |

| Transparent label length | More than 5mm |

| Internal diameter of paper tube | Around 4“(101.6mm) |

| Outside diameter of paper tube | Less than 500mm |

| Power supply | 1.5-2KW,220V 50HZ 1PH |

| Overall dimension | L3000mm×W1200mm×H2200mm |

| Weight | 1500Kg |

Electric Configuration

| PLC | Panasonic/Japan |

| Touch Screen | Weinview/Japan |

| Sensor | SICK or Pansonic/Germany Japan |

| Servo system | Panasonic/Japan |

| Transducer | Schneider/France |

| Small power AC motorc | STS/Taiwan |

| Low-voltage apparatus | Schneider/France |

| Bearing | NSK/Japan |

| Timing belt | GATES/USA |

| Frame | SUS304(Food Grade)/Shanghai |

Machine Introduction&Features

All things are possible with a shrink sleeve solution. Whether it’s dealing with difficult packaging shapes or reducing the amount of wasted materials, all machinery can be customized to fit your needs.The double head shrink sleeve labeling machine is mainly aim to sleeve label to the bottle neck and bottle body at the same time,with high efficiency for your labeling process.

Running with cosmetic , food & beverage bottle , water bottle, fruit juice bottle, tea drinks, dairy bottle and jar products, pure water bottle, condiments bottle, beer and sports drink bottle etc.

Label the bottle neck and body at the same time,Suitable for full body labeling or tamper evident banding.

The machine only applies the sleeve label when a bottle is present, which helps to save materials and reduce waste.

This system allows the machine to cut the sleeve label accurately, which ensures that the label fits perfectly on the bottle.

The speed of the machine can be adjusted depending on the cut length of the sleeve. It can handle a wide range of bottle sizes and shapes.

Servo driven output for fast and accurate delivery.

Easy to use touch screen display with job memory.

It is used to detect printed marks on the sleeve or label, which ensures that the machine cuts the sleeve label accurately.

Product Gallery

Product Details

| Name | Description | |

|---|---|---|

|

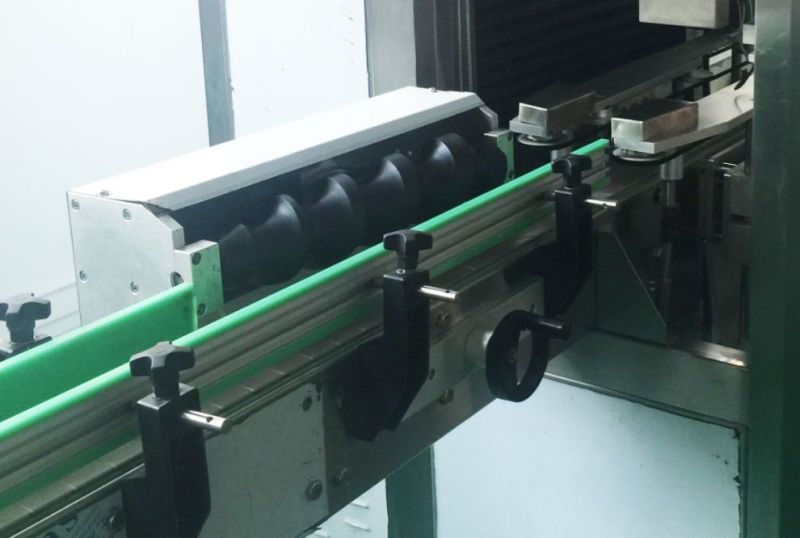

Bottle Feeding Device | Automatically separate the bottle via a bottle divider to transport the bottles at equal distances, to facilitate the insertion of labels. |

|

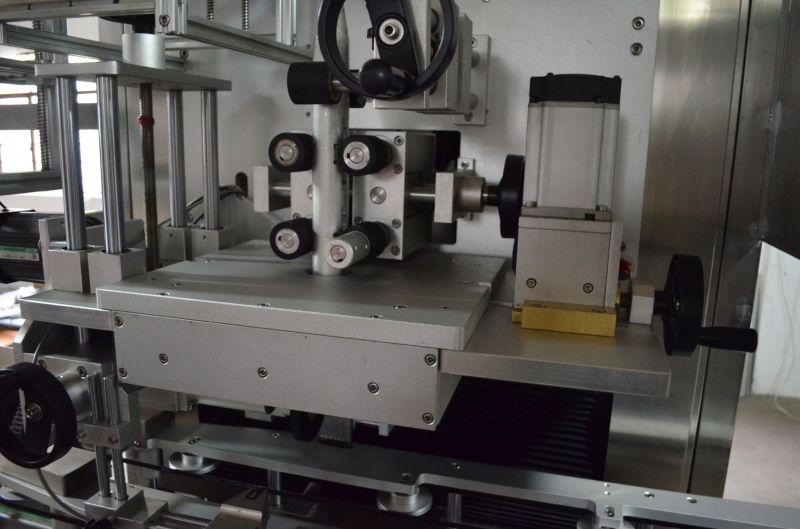

Center Pillar | Insert the shrink sleeve label material into the expanding device, so that the film material can be transported and cut.Needs to be changed according to different bottle diameter. |

|

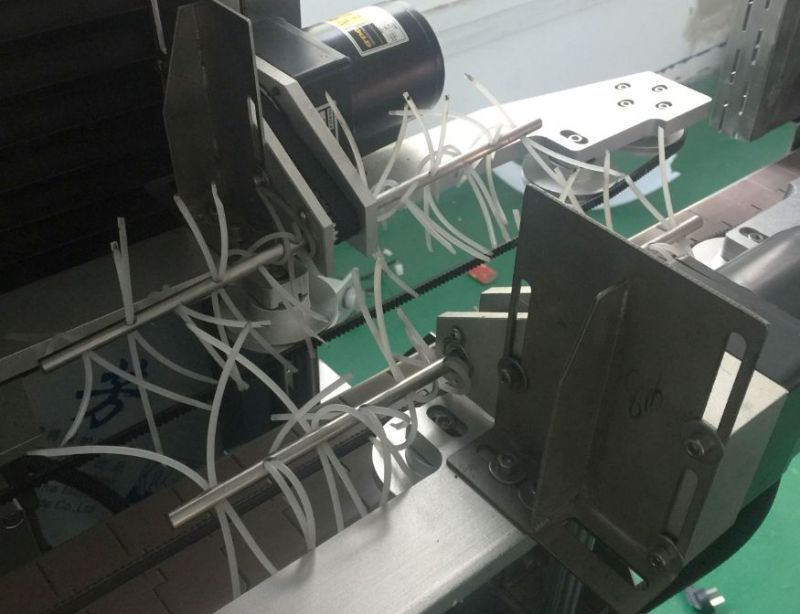

Cutter Head Unit | Unique design knife plate, in the determined range, can change the knife base. Knife changing quickly and conveniently |

|

Bottle Carrying Unit | Both sides rotate synchronously, and the height and bottle clamping position are adjusted by only one handwheel on each side, so that the bottles do not shake during transportation and the setting of label insertion height is facilitated. |

|

Brushing Unit | Using rubber brush, the labels attached to the bottles are brushed and positioned. |

|

Touch Screen | By utilizing an LCD touch screen design and an intelligent operating system with PLC control, we can ensure that the machine provides quick and accurate feedback. |

FAQs

Our labeling machines are versatile and can label a variety of products, including round objects,suqare objects and objects with flat surface etc.

There are sleeve labeling machine,hot melt glue labeling machine,self-adhesive labeling machine and cold glue labeling machine,can meet your different labeling request.

Yes, our labeling machines are compatible with various container materials, including plastic, glass, and metal.

Yes, it can handle various label sizes and shapes, including wrap-around, front and back, and top and bottom labels.

Our labeling machines use advanced sensors and precision mechanics to ensure accurate label position, even on irregularly shaped containers.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!