Hot Filling Machine

Our juice filling machine is an essential piece of packing equipment for any beverage production line that requires the filling of high-temperature liquids. It is designed to be efficient, accurate, and reliable, and it can help to ensure that the beverage products are of high quality and safe for consumption

Technical Parameter

| Model | PGF-18-18-6 | PGF24-24-8 | PGF32-32-12 | PGF40-40-12 |

| Capacity | 5000BPH | 8000BPH | 10000BPH | 12000BPH |

| Air Pressure | 0.7Mpa | 0.7Mpa | 0.7Mpa | 0.7Mpa |

| Air Consumption | 0.8m3/min | 1.0m3/min | 1.2m3/min | 1.5m3/min |

| Working Location | rinse 18 filler 18 capper 6 | rinse 24 filler 24 capper 8 | rinse 32 filler 32 capper 12 | rinse 40 filler 40 capper 12 |

| Voltage | 380V | 380V | 380V | 380V |

| Power | 5.18KW | 6.58KW | 8.18KW | 9.18KW |

| Bottle Volume | 350ml-1500ml | 350ml-1500ml | 350ml-1500ml | 350ml-1500ml |

| Machine Dimension | L2300*W1680*H2100mm³ | L2850*W2300*H2500mm³ | L3550*W2650*H2700mm³ | L4360*W3300*H2700mm³ |

| Weight | 3500KGS | 5500KGS | 6000KGS | 6800KGS |

Electric Configuration

| PLC | Mitsubishi |

| Touch Screen | Mitsubishi |

| Frequency Converter | Mitsubishi |

| Motor | Taian |

| Contactor | Schneider |

| Hot Relay | Schneider |

| Approaching Switch | Schneider |

| Photoeletric Switch | Autonics |

| Pneumatic Components | Airtac |

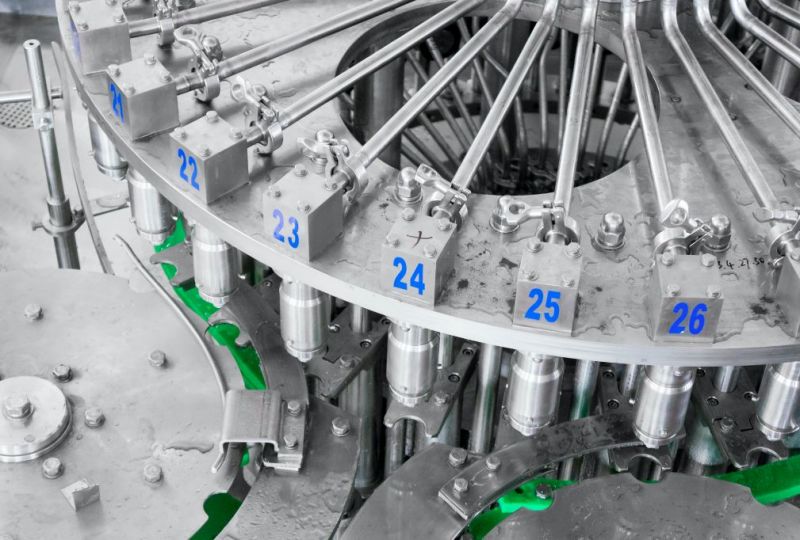

Machine Introduction&Features

The fruit juice beverage filling machine is suitable for the production of various fruit juice beverages, such as orange juice, mango juice, strawberry juice, blueberry juice, apple juice, pear juice, etc. With minor component replacements, it can also be used for filling purified water and mineral water. The machine operates on the principle of micro-negative pressure gravity filling, which ensures fast, stable, and accurate filling. It is equipped with a comprehensive material reflux system that can independently re-inject gas during reflux, without coming into contact with the material, thus reducing secondary contamination and oxidation.

The machine is designed to perform three functions, including washing, filling, and capping of bottles or containers.

The machine can fill and cap a large number of bottles or containers at a high speed, resulting in increased production efficiency.

The machine is equipped with sensors and control systems that enable it to operate automatically, reducing the need for manual intervention.

The machine is designed with simple and easy-to-maintain components, making it easy to clean and repair.

The machine may have customizable settings that allow operators to adjust the filling and capping parameters to meet their specific production requirements.

The machine is constructed with materials that meet food-grade standards, ensuring the safety and quality of the final product.

The filling equipment for fruit juice beverages features a human-machine interface touch screen control system with automatic lid supply control, temperature monitoring and automatic alarm for high temperatures, automatic stoppage and backflow for low temperatures, no lid no filling, waiting for bottles to be filled, and automatic stoppage for lid shortage.

Product Details

| Name | Description | |

|---|---|---|

|

Washing Part | The washing section of the filling machine responsible for washing bottles is a rotary bottle washing. It is primarily used for rinsing new bottles for beverages and drinking water. The main structure of the equipment that comes into contact with the rinsing medium and the external cover is made of stainless steel, including the stainless steel clamps. The machine has a simple structure that is easy to adjust, and the contact area with the bottle neck is minimal, reducing the risk of secondary pollution. Furthermore, the machine has a water collection tray to recycle the rinsing water. |

|

Filling Part | The filling section is responsible for filling the material into the washed bottles provided by the bottle washing machine, using a pressure filling and negative pressure reflux method. This filling method is quick and responsive, and provides high precision filling. The filling valve has no spring, so the material does not come into contact with the spring and can be easily cleaned. To ensure the filling process and to address filling issues, the filling valve is designed to maintain a slight backflow of material when there is no bottle present or when the machine is stopped. The filling cylinder adopts a full-cylinder filling method to ensure the stability of pressure inside the cylinder. |

|

Capping Part | The capping section is powered by a reduction gearbox which drives the turntable to rotate, causing the caps to be expelled from the hopper by the centrifugal force. A positive and negative cap separation device is situated at the outlet. If a negative cap is detected, it is automatically blown back into the hopper by an air current. Only positive caps can enter the chute and be conveyed to the cap feeding tray. The number of caps in the hopper is detected by photoelectric switches which control the cap conveyor and ensure that capping is performed effectively. To prevent accidents, an anti-reverse mechanism is installed on the chute, and a pair of photoelectric switches are positioned to stop the machine immediately if no cap is detected. |

FAQs

Our filling machines are designed to fill various types of beverages including carbonated and non-carbonated soft drinks, juice, tea, water, and sports drinks.

Our filling machines have a production capacity are depending on the products.

Yes, our filling machines are capable of filling different bottle sizes and shapes, including PET, glass, and aluminum cans.

Our filling machines can handle a minimum fill volume of 50ml and a maximum fill volume of 5 liters.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!