Horizontal type round bottle labeler

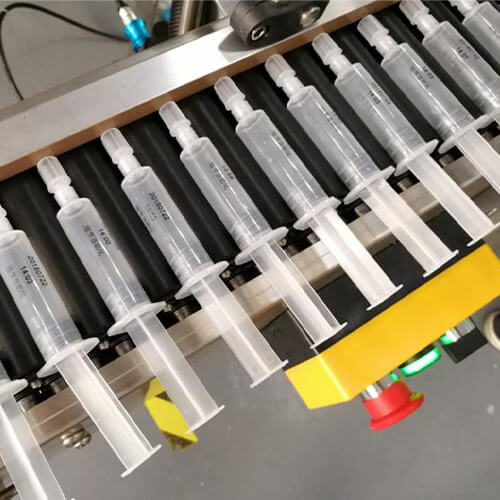

The horizontal wrap-around automatic labeling machine is designed for labeling non-stable cylindrical products, such as ampoules, carpules, tubes, pens, syringes, lipsticks, smoke flares, cartridges etc.

Technical Parameter

| Model | BGJ-W500 |

| Labeling speed | 80-100pcs/min |

| Labeling material | Self-adhesive sticker, opaque or transparent label |

| Applicable product diameter | 15-22mm |

| Applicable label size | L:20-80mm,W:20-80mm |

| Labeling precision | +/-1mm(exclude the product and label deviation) |

| Power supply | 220V 50HZ |

| Overall dimension | L1660mm×W650mm×H1500mm |

| Weight | 250Kg |

Electric Configuration

| PLC | FX3sA-30MT/Mitsubidhi |

| Touch Screen | TK6070iP/Weinview |

| Sensor | D10BFP/Banner |

| Labeling Motor | 2S86Q-030B8/KINCO |

| Labeling Motor Drive | 2M860/KINCO |

| Converyor Motor | D63B14-0.18KW+FB/Li-ming |

| Frequency converter | S800-2S0.4G/SAVCH |

| Emergency Stop | XB2-BS542/Omron |

| Relay | LY2N-J 24VDC/Omron |

Machine Introduction&Features

The labeling system boasts a range of features that make it highly efficient and reliable. With its minimal moving parts and easy adjustment and changeover capabilities, it is simple to operate and maintain.

Additionally, the angled roller conveyor is custom-designed to suit the shape and size of the labeling objects, ensuring unparalleled accuracy during the labeling process.

Pharmaceutical industry,beauty industry,pen manufacturing industry.

Ampoules, carpules, tubes, pens, syringes, lipsticks.

The auto feeder design and slanted conveyor are made from special engineering plastic rollers.

The main materials of the equipment are stainless steel and high-grade aluminum alloy, with a solid and elegant overall structure,simple operation and maintenance.

The equipment can be expanded to include label printing systems such as thermal transfer printing, thermal inkjet, continuous inkjet, or hot stamping devices.

Furthermore, optional vision systems can be incorporated to guarantee quality criteria such as print data correctness and label placement on your products, helping to prevent complaints and ensure customer satisfaction.

Product Gallery

Product Details

| Name | Description | |

|---|---|---|

|

Auto-Feeder | Auto feeder design and slanted conveyor made from special engineering plastic roller, aviod the potential damage to fragile containers. |

|

Spoke Guard Mechanism | The function of making labels adhere is achieved by components such as spoke motor, spoke belt, etc. |

|

Labeling Head | This is the part of the machine that applies the label to the product. The labeling head typically includes a labeling mechanism that dispenses the label onto the product and a conveyor that moves the product through the machine. |

|

Touch Screen | The touch screen serves as the main interface for controlling the labeling machine. It allows operators to start and stop the machine, adjust settings, and control various labeling parameters. |

|

Conveyor System | It is an important component, which transports the products to be labeled from one position to the labeling position, ensuring smooth transportation of the products and accurate labeling.can be adjusted and customized according to the size and shape of different products. |

|

Electrical Control Cabinet | It houses the electrical controls and components necessary for the machine's operation. There are Power Distribution,Motor Control,Sensors and Detectors,Safety Components,Communication Interfaces,Wiring and Terminal Blocks ect. |

FAQs

The horizontal labeling machine is specifically designed to accommodate horizontal labeling of slim, non-freestanding cylindrical containers such as pens, test tubes, syringes and lipsticks.

By using the unique auto feeder design and the slanted conveyor made from special engineering plastic roller, potential damage to fragile containers are minimized. This labeler is designed for containers that are 10-25mm in diameter.

Yes, utilizes PLC based control panel in the form of an advanced touch screen. The controls are easy to learn and simple to operate.

Yes, this machine can run independently or be integrated into an automated packaging line.The conveyor can be extended: the length may var y based on selected options.

Yes,the machine can be eqipped with Lot/Date Coding,Custom made Wrap Station,Custom Product Loader and Automatic Vertical Stand-up Accumulation System etc.

The machine all made up of stainless steel and aluminum alloy from main board, main frame, conveyor belt table, legging, to interface.

When labeling, the bottle will automatically rotate to allow the labeling device to apply the pressure for labeling.Automatically detect the product length and labeling position of containers to prevent mislabeling.

High quality labeling, correct label belt be in right position, label cover label accurate, rolling and nobbing press label result in an even, no scrape, no air bubble on ever product.

Yes, free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!