Revolutionize your production line with our latest bottle blowing technology.

We provide four main types of blow molding machines: high speed PET blow molding machine, automatic economical blow molding machine, big bottle blow molding machine and semi automatic blow molding machine. We offer complete PET blow molding solutions to our customers

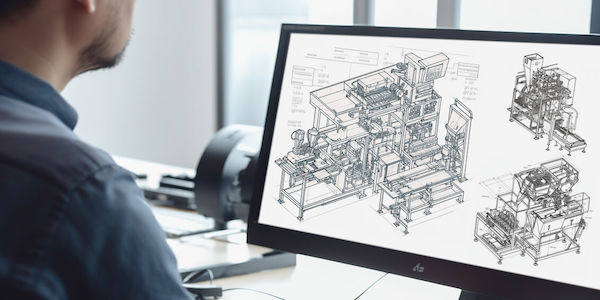

Our Equipments

A blow molding machine is used to manufacture plastic bottles and containers by melting plastic material and blowing it into a mold cavity. It comes in different types for various applications and can produce bottles in different sizes, shapes, and colors.+

Pre-sales and After-sales services

Pre-Sales Services:

- Design drawing

- Precise quotation

- Free-testing if necessary

After-sales Services:

- 24 hours online after-sales services

- Remote assistance for commissioning and installation

Cooperation Process

Standard

What Customers Say

FAQs

The process starts by melting plastic resin and then injecting it into a mold. Once the plastic has cooled and solidified, a hollow tube called a parison is formed. The parison is then clamped into a mold and air is blown into it, causing it to expand and take on the shape of the mold.

There are several types of blow molding machines, including extrusion blow molding machines, injection blow molding machines, and stretch blow molding machines.

High production efficiency, the ability to produce large quantities of products with consistent quality, and the ability to create complex shapes and designs.

It can work with the thermoplastic materials, including HDPE, LDPE, PP, PVC, PET, and others.

Yes, our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

What can be equipped with?

Get Your Free Quote Now!