Palletizing robots have revolutionized various industries, alleviating the burden of manual labor and driving technological advancements.

These machines have reshaped production lines and gained prominence across multiple sectors.

We offer insights into the incredible benefits of palletizing robots and their potential for future advancements.

Let’s explore how these robots are enhancing businesses and shaping the future of automation and efficiency.

Advantages of Palletizing Robots in Diverse Industries

Palletizing robots have brought significant advantages to the market,

simplifying tasks and liberating workers from laborious duties.

With advancements in science and technology, these robots have continuously evolved,

gaining recognition for their versatility and skills.

Let’s delve into how palletizing robots can benefit various industries,

with the assistance of Shanghai Xingpai Automation.

Versatility and Efficiency

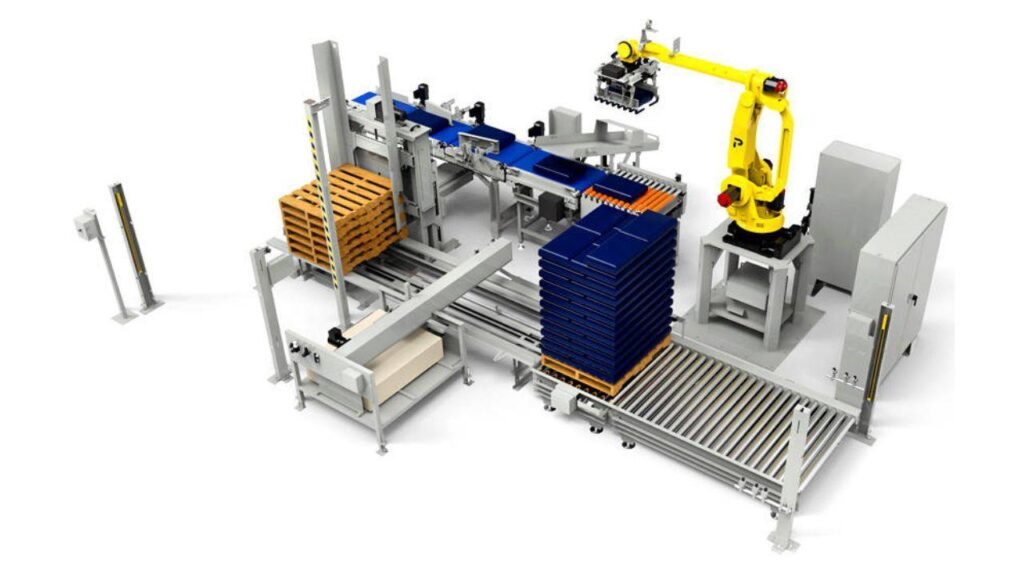

Palletizing robots excel in their ability to perform diverse tasks. Their flexibility allows them to handle different operations while occupying minimal space.

As their popularity surges, these robots are widely adopted in sectors such as agriculture, healthcare, food, petrochemicals, and household goods.

Their success hinges on factors such as job performance, structural stability, size, and overall efficiency.

Meeting Growing Demands

In an ever-evolving business landscape, the demand for faster operations continues to rise.

Manual palletizing struggles to keep pace with these requirements.

Manual work is only feasible with lightweight materials, frequent changes in sizes and shapes, and low output.

Palletizing robots fill this gap, enabling businesses to achieve more. They can replace human workers in hazardous, dangerous, cold, or hot environments, handling tedious and repetitive tasks.

By augmenting human capabilities, these machines enhance productivity and maintain consistent work quality.

Palletizing robots streamline box stacking processes, ensuring efficiency, faster cycle times, and higher yields.

Moreover, their exceptional accuracy reduces errors and enables precise placement, making retrieval effortless.

Ease of Use and Cost Savings

Palletizing robots feature user-friendly interfaces, simplifying configuration changes and ensuring seamless operation.

These robots operate autonomously, eliminating the need for human intervention and resulting in substantial cost savings on wages.

Furthermore, the bright future of box-stacking robots lies in their fusion of mechanical and computer technologies.

As automation and artificial intelligence progress, these robots will continue to advance in intelligence and strength.

This growth enables businesses to operate more efficiently, driving improved overall performance.

Future Development of Palletizing Robots

Palletizing robots have experienced rapid advancements in recent years,

aligning with the industry’s trend of producing a diverse range of goods in smaller quantities.

These small and flexible robots have gained popularity, enabling efficient handling of different materials and adaptable construction plans.

As various companies embrace palletizing robots, their future trajectory becomes increasingly important.

Increased Automation Level

The future of palletizing robots lies in their increasing automation.

The combination of mechanical and computer technologies enhances the intelligence and autonomy of these robots.

Microelectronics, heat sensors, and other advanced devices drive automation, elevating the quality of work performed.

Integration of microcomputers further refines the capabilities of palletizing robots, ensuring high-quality output.

High-Speed Operation

Continued focus on high-speed operations is another area for future growth in palletizing robots.

While some machines already possess impressive speed, ongoing developments aim to enhance overall system performance.

Advancements in automation and robot structure contribute to improving output rates and workflow efficiency.

Diversification of Functions

In response to evolving markets and the need for smaller batch sizes, palletizing robots are diversifying their capabilities.

The demand for robots adaptable to varying environments and products has prompted these machines to expand their functionality.

This flexibility enables efficient palletizing across a wide range of scenarios, optimizing productivity, efficiency, and adjustability.

Conclusion

Palletizing robots have become indispensable tools for businesses, offering cost savings, increased speed, and time efficiency.

Their widespread adoption is attributed to their versatility, adaptability,

and ability to perform diverse tasks.

Looking ahead, palletizing robots will become more automated, achieve higher operational speeds,

and exhibit enhanced multi-functionality.

If you are considering implementing palletizing robots or have any inquiries, please contact us.

Explore our blog for more informative posts on this subject.

Embrace the potential of palletizing machines to unlock new growth opportunities for your business.