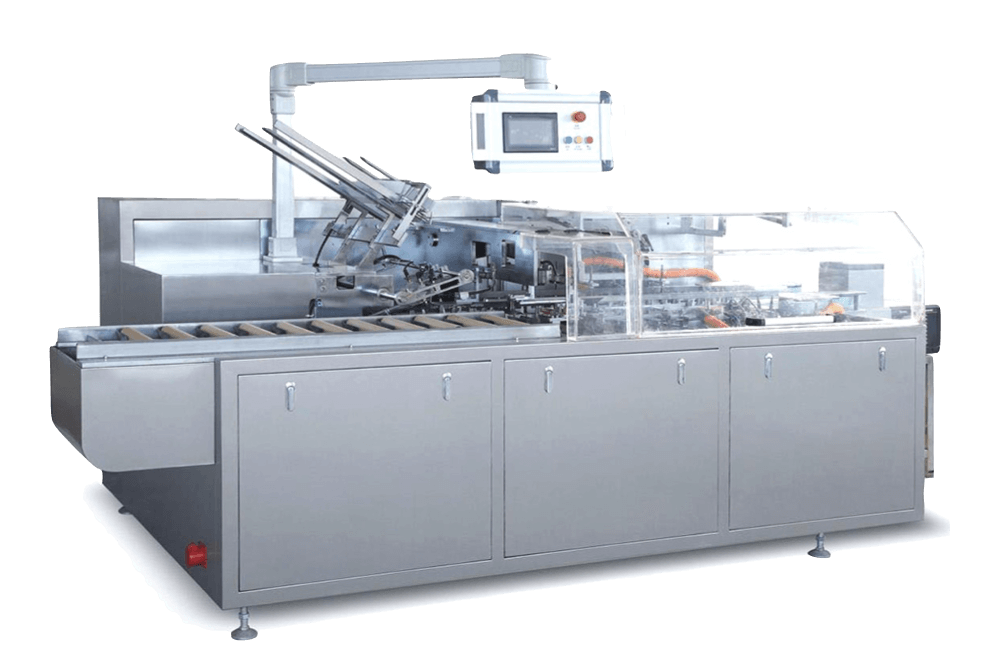

CSZ-450C Preservation Film Cartoning Machine

Mainly customized for preservative film, aluminum foil rolls, napkins, and other consumer goods.

Technical Parameter

| Model | CSZ-450C |

| Packing speed | 40-50cartons/min |

| Size of package | L(100-450)mm×W(30-70)mm×H(30-70)mm |

| Cardboard material | 250-450g/㎡ |

| Instruction material | 60-70g/㎡ |

| Instruction size (Unfold) | (80-150)x(90-170)mm |

| Instruction size (Fold) | (1-4)Fold |

| Motor power | 1.5kw |

| Power supply | 380V50HZ |

| Minimum Air pressure | “0.5-0.8Mpa” |

| Air consumption | 120-160L/min |

| Maximum noise | 80dB |

| Overall dimension | L3400mm×W1174mm×H1800mm |

| Weight | 1500Kg |

Electric Configuration

| PLC | CPIE-N30DT-D/Omron |

| PLC Extened Module | CPIE-C1F11/Omron |

| Touch Screen | NB7W-TW00B/Omron |

| Sensor | E3Z-D61/Sick |

| Frequency | 3G3JZ-A4015/Omron |

| Relay | MY2 NJ24V/Omron |

| Button | XB2/Schneider |

| Emergency Stop | ZB2 BC4D/Schneider |

| Electromagnetic Valve | 4V210-08/Airtac |

| Pressure Regulator Valve | BFR-2000/Airtac |

| Proximity Switch | TL-Q5MC1/Omron |

| AC contactor | LC1E3210M5N/Schneider |

| Air switch | 3P32A 1P6A/Schneider |

| Vaccum Sounder | ABM20-C/SMC |

Machine Introduction&Features

TheCSZ-450C cartoning machine is a smart packaging solution that can handle a variety of consumer goods such as preservative film, aluminum foil rolls, and napkins, with a packaging speed of 80 cartons per minute. It accommodates packages ranging from 100-450mm in length, 20-80mm in width, and 20-90mm in height, while also offering customized options for special sizes.

The cartoner is controlled by a programmable logic controller (PLC) and features electrical components supplied by renowned international brands such as Omron from Japan.

With its automatic detection capabilities, the machine can verify the number of items and check if cartons and items are in place before initiating operations. It also prevents carton suction or glue spraying when there is no material to feed.

The machine provides automatic displays of fault alerts, packaging speed, and the number of finished items, streamlining the monitoring process.

The mechanical feeding mechanism ensures stable performance and stops at the expected position, contributing to the overall reliability of the machine.

Customizable options include the addition of a material bucket to the conveying belt, which synchronizes with the belt for automatic feeding, eliminating the need for manual intervention and increasing the speed of packaging.

The machine is encased in a high-quality shell made of stainless steel and aluminum, with electrical components sourced from trusted German brands, ensuring a durable and reliable performance.

Product Details

| Name | Description | |

|---|---|---|

|

Feeding System | It is the loading unit, allowing materials to be packaged. |

|

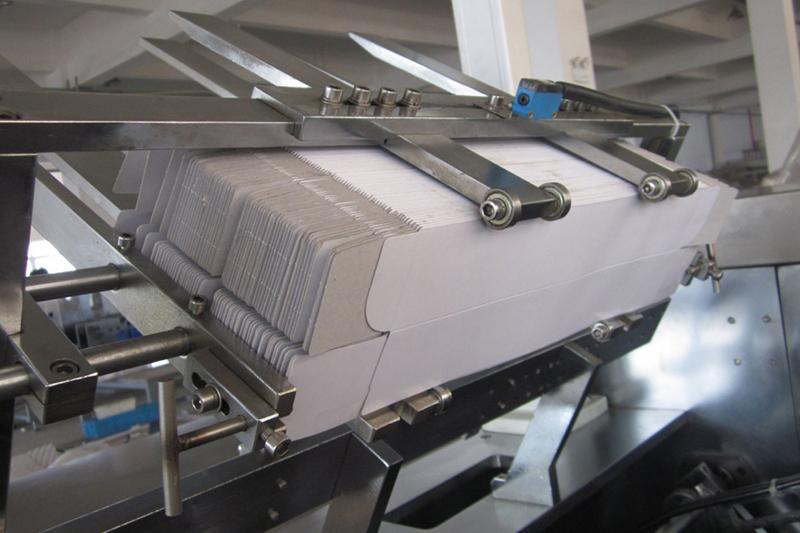

Box Forming Device | The suction cup opens the carton precisely and quickly. It will send the carton to the bottom of the suction cup, then place it in chains. |

|

Box Storage | The carton store has a board that can move to adjust the package length. Both the front and back frame are connected by a slot hole in order to fit different packaging widths. |

|

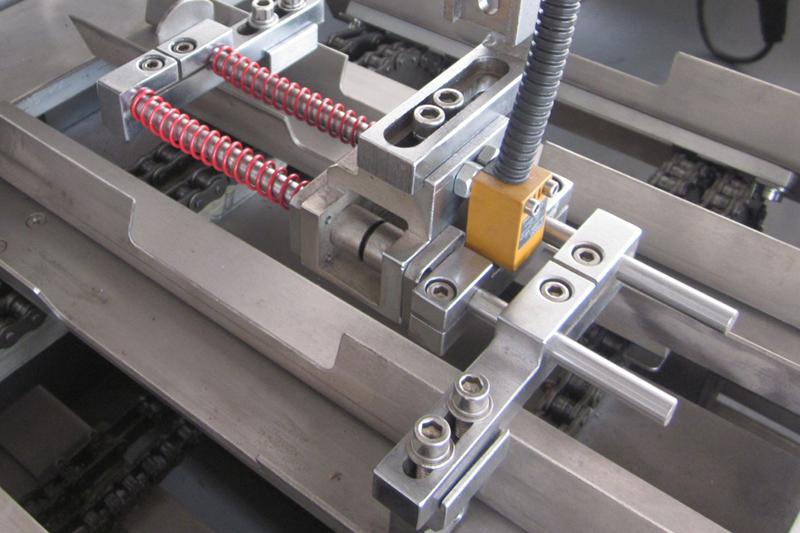

Material Pushing | It can push the materials firmly and package items stably. |

|

Inner Flap Closing | Inner flap closing station, inner flaps can seal the carton firmly after items being packed. |

|

Hot Melt Glue Sealing | Hot melt glue device, it can seal the carton and send the finished product out. |

FAQs

Mostly used in food, pharmaceuticals, and consumer industry.

Yes, definitely can be customized as your products.

It depends on your products size and the model of the machine.

Yes, cartooning machines are designed to be user-friendly and easy to operate.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!