Handle your packaging needs with ease and efficiency.

We provide three main types of carton packing machines: drop type case packer, grip type case packer and wrap around case packer. We offer customized packaging solutions based on our clients’ unique product specifications and production line requirements

Our Equipments

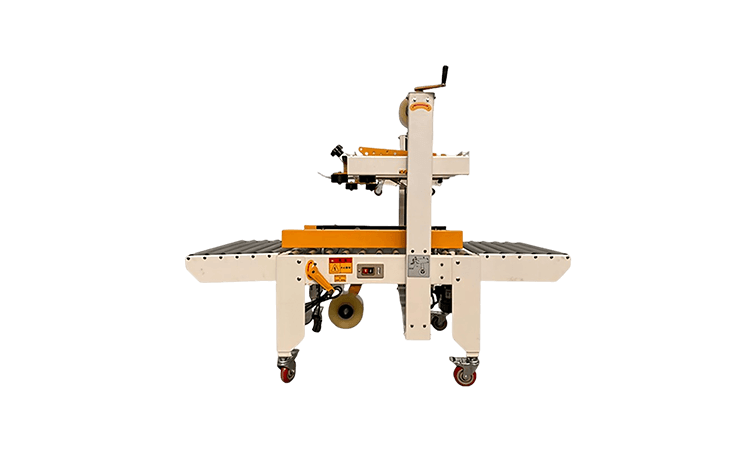

Carton packing machineused for the automated packaging of products into pre-formed cardboard boxes or cartons. The machine picks up the products from a conveyor belt and precisely places them into the cartons, which are then sealed, labeled, and often palletized for shipment.

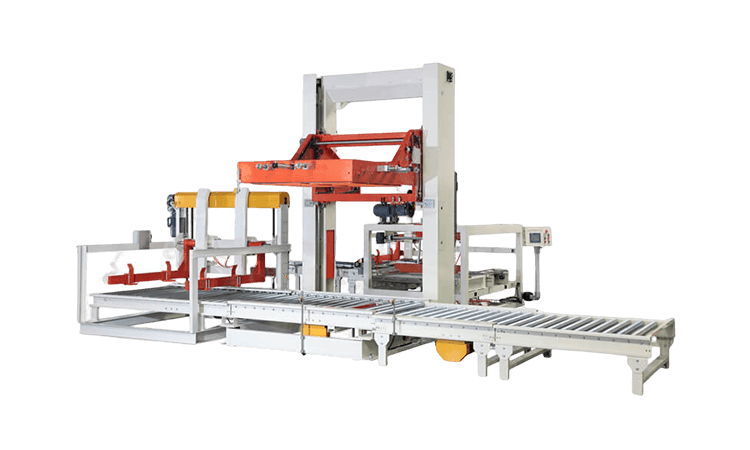

Our wrap around carton packer arranges bottles into a specific pattern before conveying them onto a case, which is then moved horizontally to complete the automatic packaging process including forming, gluing, and sealing. This machine is suitable for automatic packaging of PET bottles, PE bottles, cans, glass bottles, and irregularly shaped bottles.

Pre-sales and After-sales services

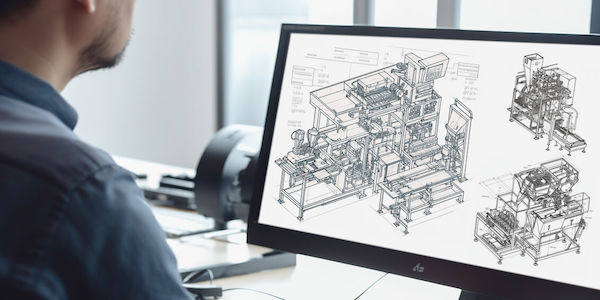

Pre-Sales Services:

- Design drawing

- Precise quotation

- Free-testing if necessary

After-sales Services:

- 24 hours online after-sales services

- Remote assistance for commissioning and installation

Cooperation Process

Standard

What Customers Say

FAQs

There are drop case packer, wrap-around case packer, and pick and place case packer.

Yes, it can be customized according to your product sizes and shapes.

Consider factors such as the product size and shape, the required packaging speed, and the desired level of automation.

Increased efficiency, productivity, and consistency in the packaging process, reduce labor costs and minimize the risk of product damage during packaging.

Food and beverage, pharmaceuticals, and consumer industry.

Yes, our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

What can be equipped with?

Get Your Free Quote Now!