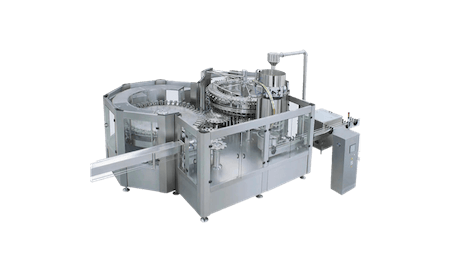

Filling Machine

We provide three main types of filling machines: water filling machines, hot filling machines, and carbonated beverage filling machines, and Each customized production line solutions based on each customer’s specific needs.

Our Equipments

Our filling machine is primarily designed for filling bottles with water, fruit juice, and carbonated beverages. It is capable of accurately controlling the amount of liquid and can fill bottles of various sizes and shapes.

Our water filling machine is suitable for various PET bottle sizes and shapes and it is used primarily for bottling purified, mineral, and mountain spring water. Provide personalized filling machine recommendations based on water quality, production speed, and origin to ensure the best fit for our customers

Our hot filling machine is a perfect solution for filling PET bottles of varying shapes and sizes with a wide range of beverages, including fruit juices, tea drinks, functional beverages, and dairy-based drinks. It is an ideal choice for optimizing your production process and ensuring efficient and high-quality filling of your products

Our carbonated beverage filling machine fills PET bottles of various sizes and shapes with drinks such as cola, soda, and sparkling water using the isobaric filling method. Provide customized recommendations based on customer requirements such as carbonation and sugar levels, as well as production volume.

Pre-sales and After-sales services

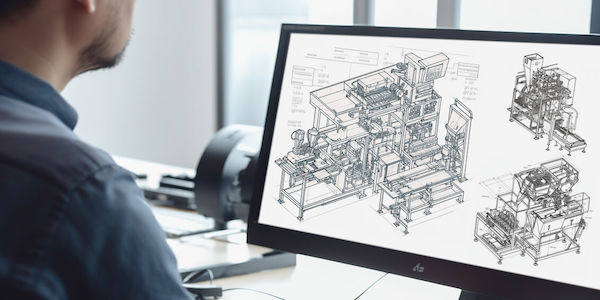

Pre-Sales Services:

- Design drawing

- Precise quotation

- Free-testing if necessary

After-sales Services:

- 24 hours online after-sales services

- Remote assistance for commissioning and installation

Cooperation Process

Standard

What Customers Say

FAQs

Our filling machines are designed to fill various types of beverages including carbonated and non-carbonated soft drinks, juice, tea, water, and sports drinks.

Our filling machines have a production capacity are depending on the products.

Yes, our filling machines are capable of filling different bottle sizes and shapes, including PET, glass, and aluminum cans.

Our filling machines can handle a minimum fill volume of 50ml and a maximum fill volume of 5 liters.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

What can be equipped with?

Get Your Free Quote Now!