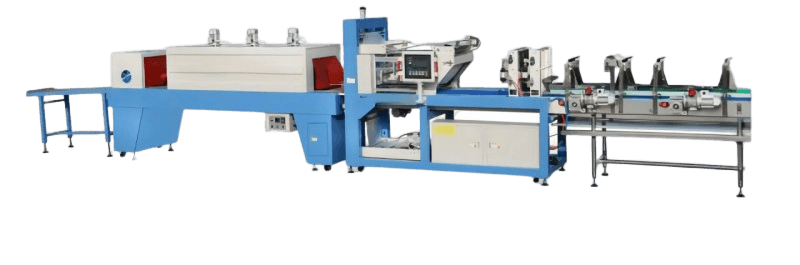

Medium-Speed Shrinking Wrapping Machine

A medium-speed shrinking wrapping machine running at a moderate speed, making it ideal for small to medium-sized production lines.Can be used for kinds of bottles.

Technical Parameter

| Model | MB-20 |

| Speed | 18-20packs/min |

| Conveyor Width | 541mm |

| Shrink Chamber | L1800mm x W650mm x H450mm |

| Shrink Temperature | 170℃-200℃ |

| Packing Form | 3*4, 4*6,or customized as your request |

| Max Packing Size | L600mm x W400mm x H350mm |

| Packing Material | LDPE |

| Film Requirment | Film roll width less than 580mm, thickness 0.04-0.10mm roll diameter less than 400mm |

| Air Consumption | 350NL/min |

| Working Voltage | 3Phase 5Line,380V 24KW |

| Working Pressure | 0.6-0.8Mpa |

| Machine Size | L13840xW1100xH2100mm |

Electric Configuration

| PLC | B&R/Austria |

| Touch screen | B&R/Austria |

| Servo motor | B&R/Austria |

| Film feeding motor | B&R/Austria |

| Spindle motor | B&R/Austria |

| Cutter servo motor | B&R/Austria |

| Frequency | Schneider/France |

| Contactor | Siemens/Germany |

| Intermediate relay | Schneider/France |

| Photoelectric | AUTONICS/Korea |

| Cylinder | FESTO/Germany |

| Pressure regulating valve | SMC/Japan |

| Conveyor gear motor | SEW/Germany |

Machine Introduction&Features

The Automatic Film Shrink Wrapping Machine is specifically designed for wrapping various products such as pop-top cans, mineral water bottles, beer bottles, drinks, etc., without the need for a bottom tray. It works in conjunction with a PE film shrink tunnel to provide a perfect packaging solution for the goods. Suitable for use in various industries, including beverage, food, and packaging.

Specially designed for fully automated packaging production lines for beer, beverages, pure water, fruit juice, dairy products, and more.

Features full automatic functions including bottle transferring and arranging, membrane packing, sealing and cutting, shrinking, cooling, and shaping.

Quick seal cooling structure ensures higher strength of seals, even in high-speed production conditions

Equipped with PLC automatic program circulation control for stable and reliable performance.

Original imported guide bar cylinder guarantees correct and durable operation.

Inductive switch controls the membrane transfer system for reliable adjustment and control of membrane transferring length with minimal loss.

Frequency changing devices control the transfer system for stable and smooth transfer speed.

Enhanced cooling shaping passage quickly turns the packaging membrane into a high-strength status for convenient storage and transportation.

Product Gallery

Product Details

| Name | Description | |

|---|---|---|

|

Bottle Feeding Conveyor | The bottle conveyor is composed of rolling guardrail, bottle separating plates, and multi-section conveyor belts, which are used to separate bottles. |

|

Bottle Sorting Device | It is used to group bottles according to packaging requirements, and then push the grouped bottles forward. |

|

Shrink Film Wrapping Device | Automatically wrap the shrink films onto the grouped bottles,and cutter the film. |

|

Shrink Tunnel | The shrink tunnel consists of a heating and shrinking section, which is responsible for heating and shrinking the wrapped packaging materials. Uses heat to uniformly shrink the film at a set temperature, tightly conforming it to the surface of the bottles. |

|

Touch Screen | The touch screen of a shrink packing machine is a modern and convenient interface that simplifies the operation of the machine, allowing operators to easily control and monitor the packaging process for efficient and effective shrink wrapping. |

FAQs

Our labeling machines are versatile and can label a variety of products, including round objects,suqare objects and objects with flat surface etc.

There are sleeve labeling machine,hot melt glue labeling machine,self-adhesive labeling machine and cold glue labeling machine,can meet your different labeling request.

Yes, our labeling machines are compatible with various container materials, including plastic, glass, and metal.

Yes, it can handle various label sizes and shapes, including wrap-around, front and back, and top and bottom labels.

Our labeling machines use advanced sensors and precision mechanics to ensure accurate label position, even on irregularly shaped containers.

Yes,our engineer will provide free design for your checking before make the final quotation.

Lead time varies depending on the specific machine and production schedule, but typically takes 6-8 weeks.

We accept a variety of payment methods, including wire transfer, credit card, and PayPal.

We offer online technical support and troubleshooting services for the lifetime of our machines, as well as parts and service support.

Yes, we provide free online training for machine operation and maintenance to ensure our customers can use and maintain machines effectively.

We offer a 1-year warranty for all of our machines, with additional warranties available upon request.

Get Your Free Quote Now!